Crushing

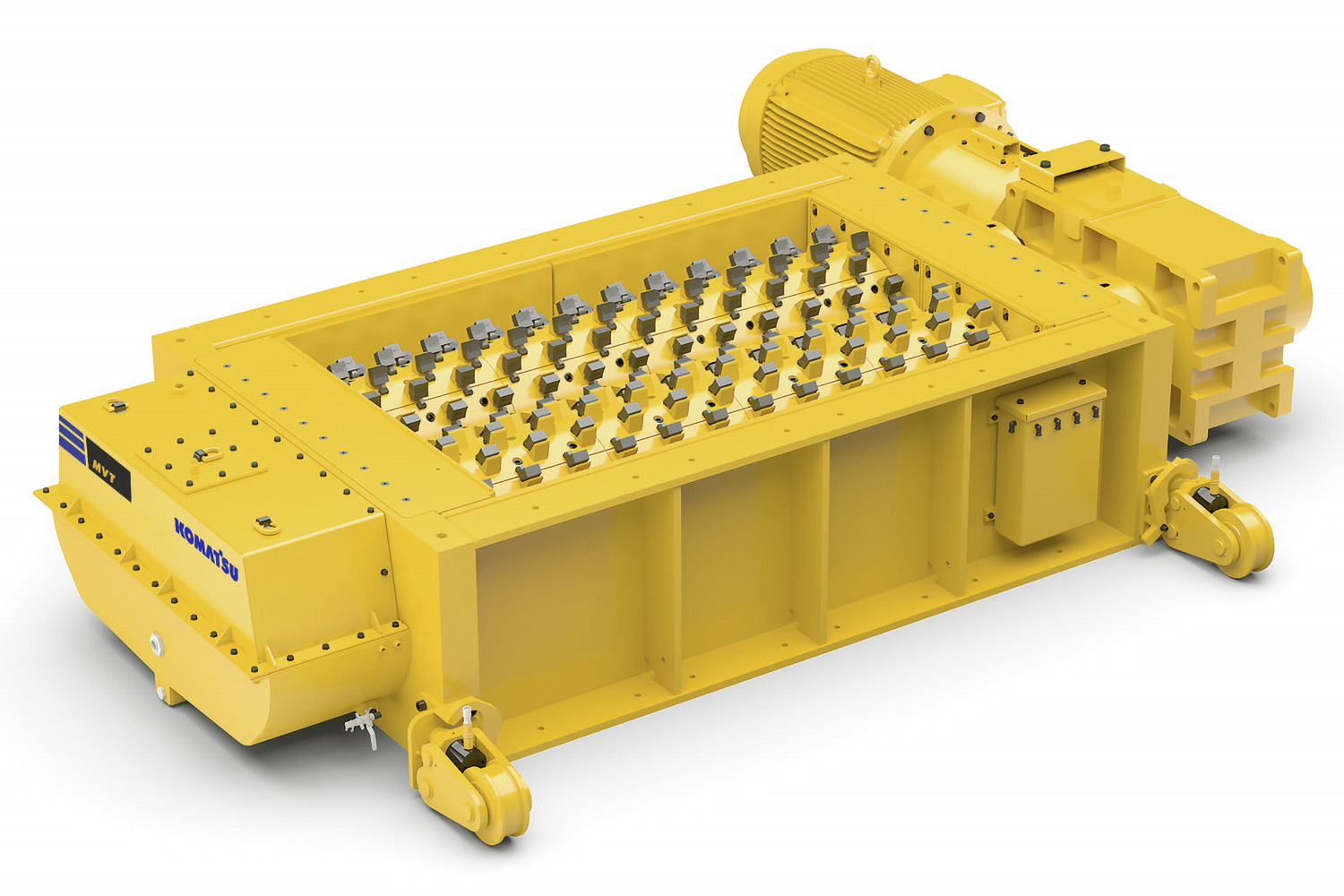

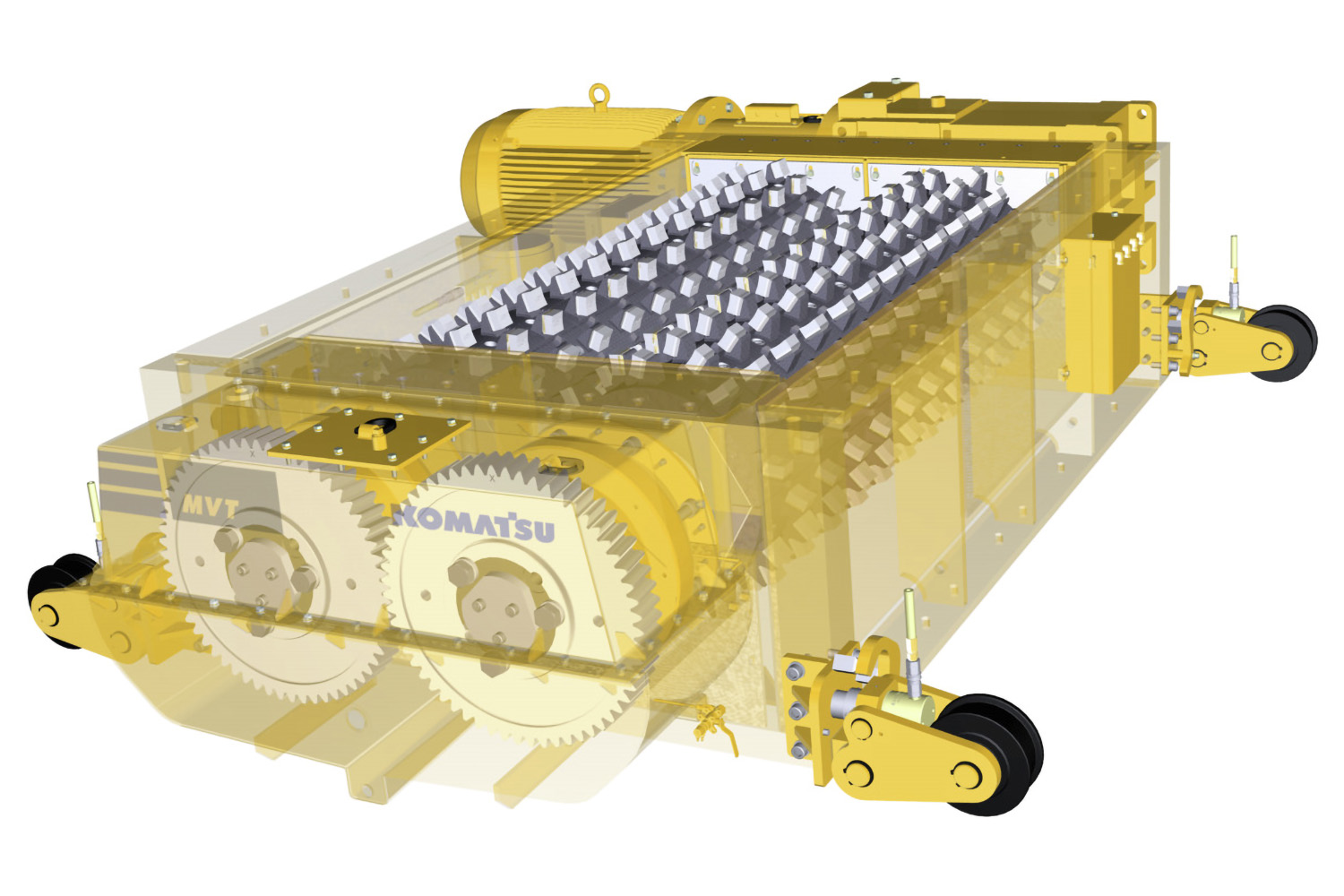

MVT-II 600

Sizers

- Capacity (MTPH) Up to 1 000

- Capacity (TPH) Up to 1,000

- Standard output product sizes (in) 1, 1.5 or 2

- Standard output product sizes (mm) 25, 38 or 50

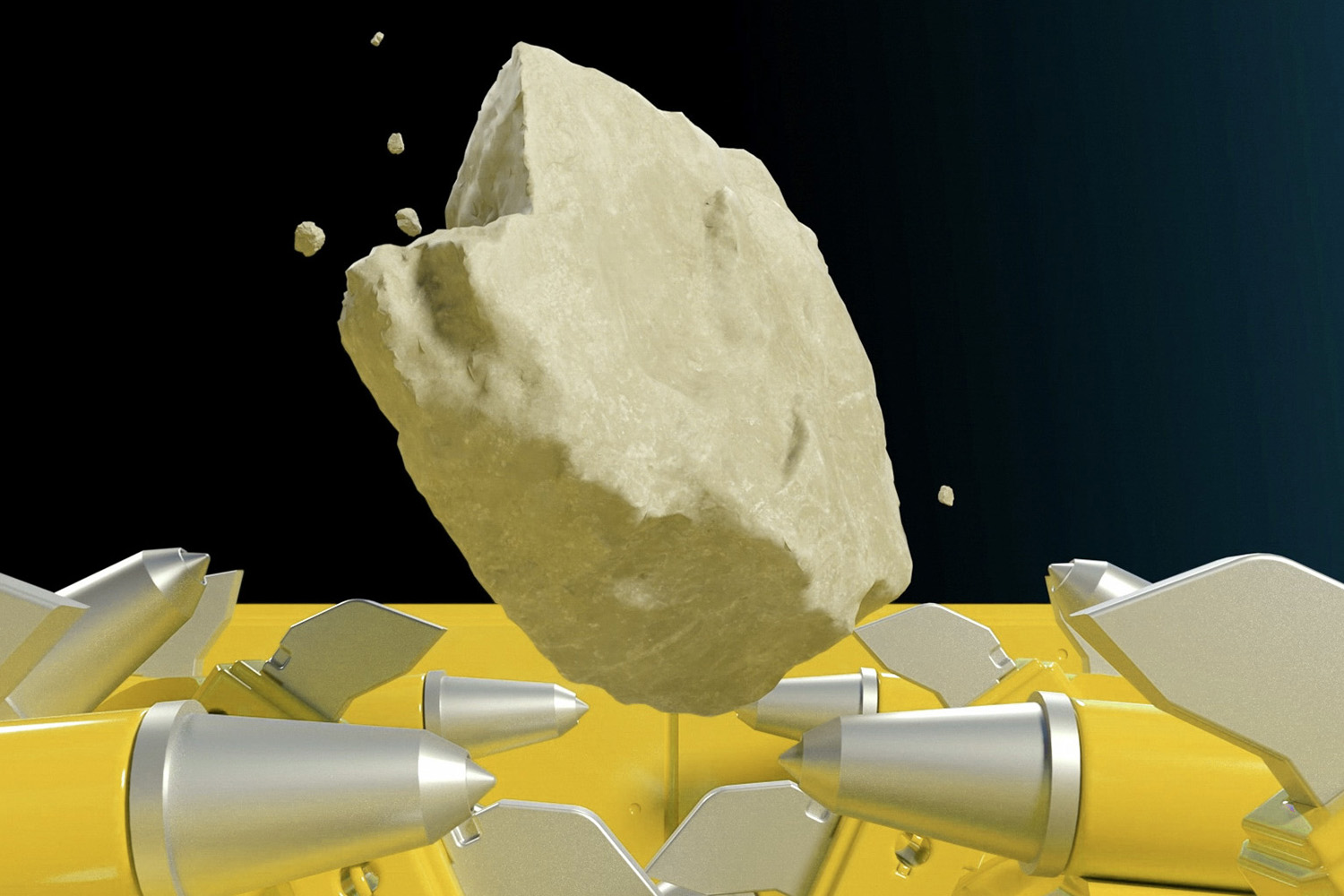

Reduce fines and abrasive wear

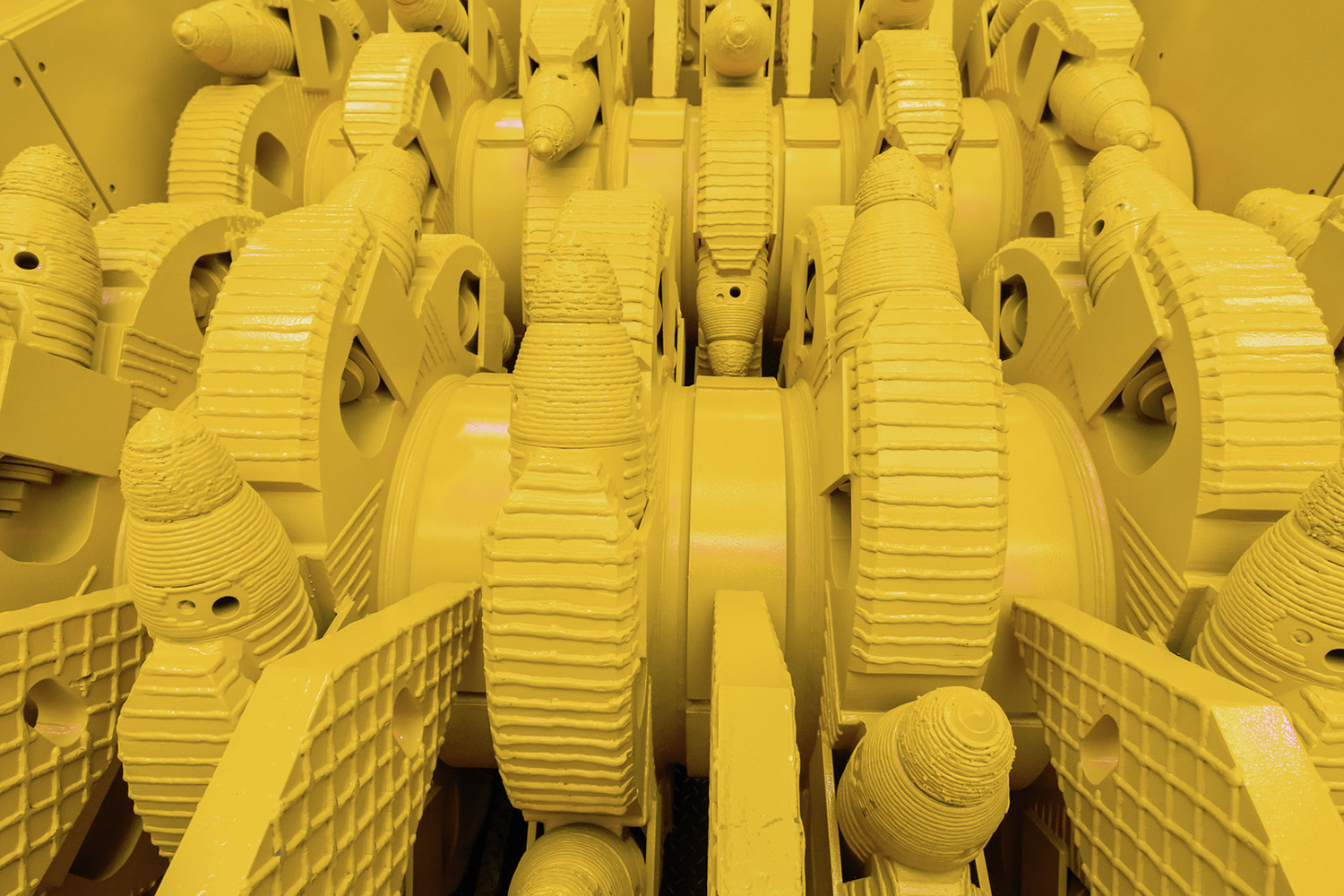

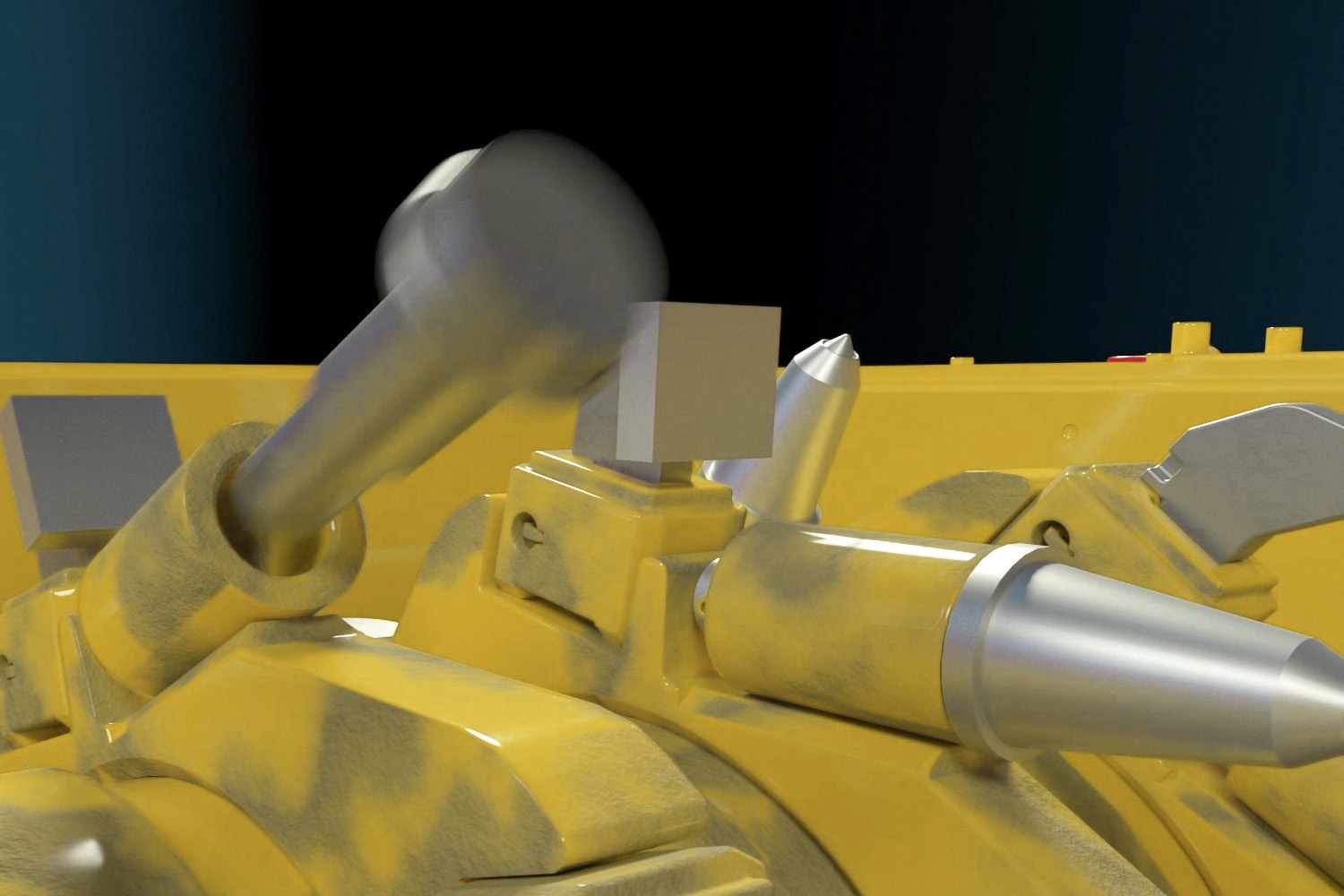

Secondary sizers use matched velocity technology (MVT) to minimize fines. Timed center-sizing rolls enable teeth to mesh together and control product size in three dimensions. Shaft assemblies include cast wear segments with replaceable teeth for extended life.

- Picks designed with long-lasting wear segments

- Designed to reduce costs

- Picks allow a harder mineral to be broken with the same force, when compared to compressive crushers

Features and benefits

Designed to improve profitability

Reduces the number of crushing/dump stations required and can work with very large lump sizes to increase crushing ratios.

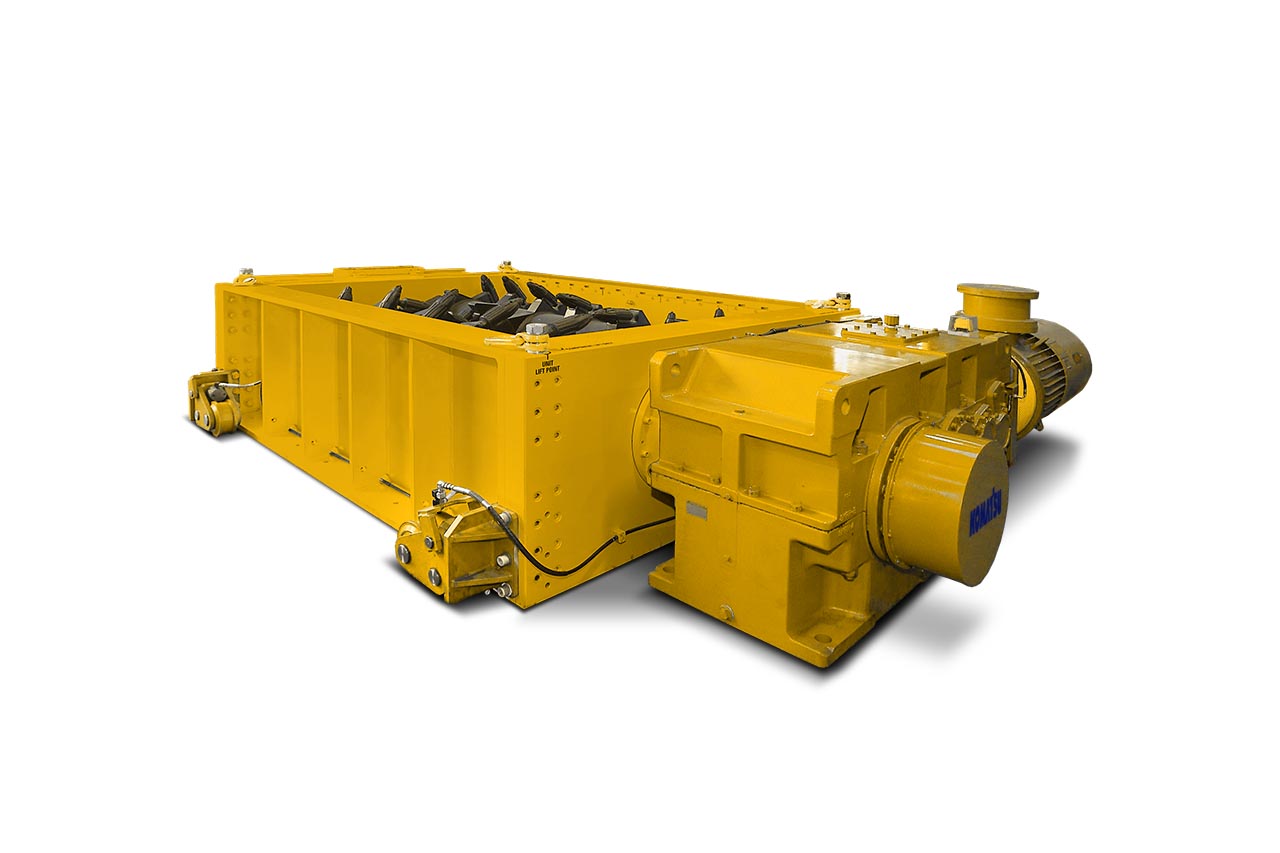

Compact footprint

Sizer can be installed where other crushers would not fit and at a potentially lower cost. Ideal for mobile or underground applications with a small machine envelope. Secondary sizers often installed between conveyor transfer points to reconcile material handling issues.

Ability to crush wet, sticky materials

Meshing action of timed center sizing shaft scrubs wet sticky material off shafts. Unlike conventional side sizing designs that can only clean between rings of teeth on the shaft, these machines handle wet, sticky minerals more easily.

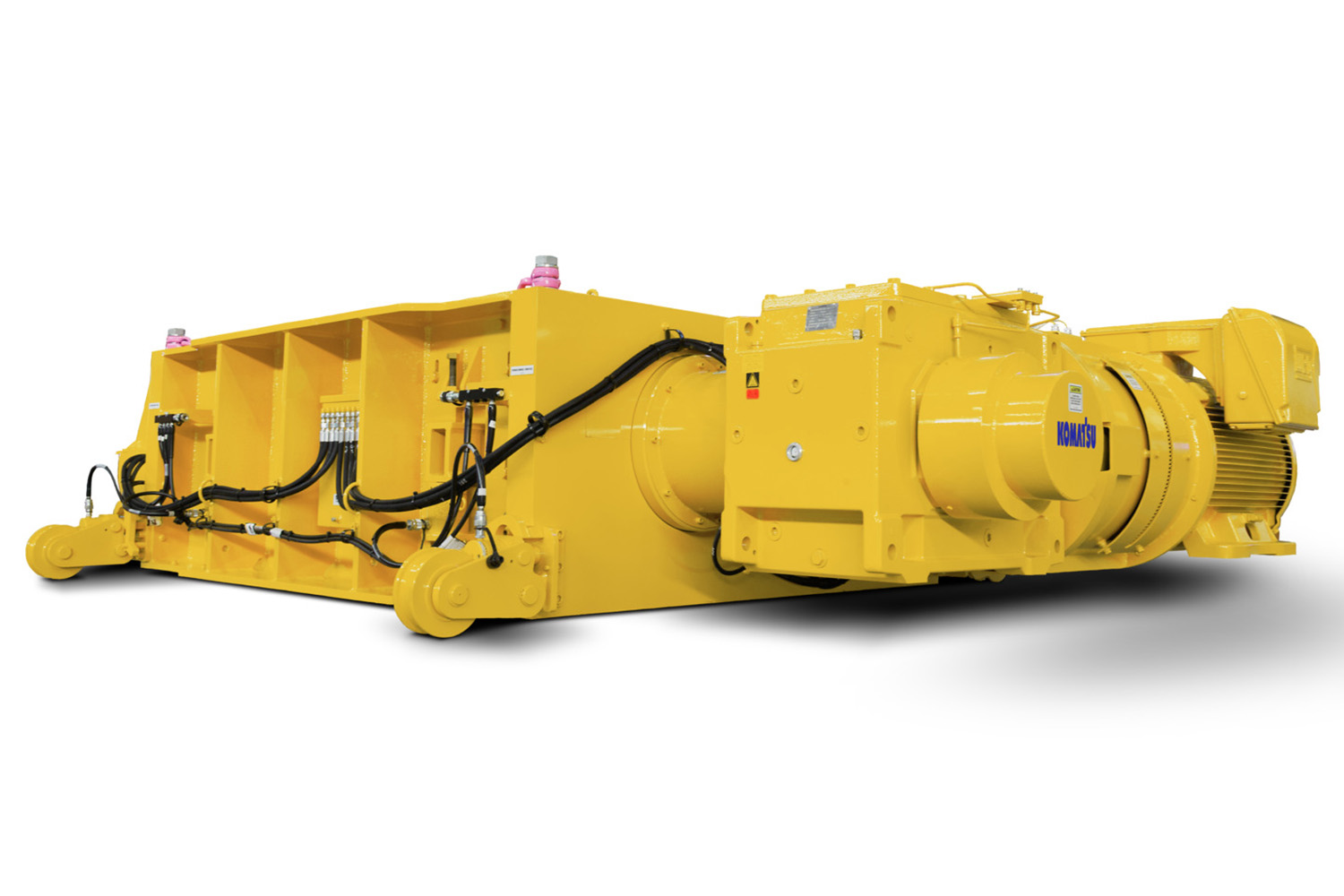

Engineered for low TCO

Minimize total cost of ownership with standard sizer accessories and controls, energy-efficient helical gear reducers, robust power transmission components, automatic lubrication system and extended life bimetallic wear components.

Minimize fines and wear

Minimize fines and wear with matched velocity technology (MVT) that aligns the tooth speed of the roll with the velocity of the mineral falling through the crusher.

Control and optimize product size

Timed shafts and oil gap adjustment enables control of product size to minimize transfer issues to chutes, transfer points and conveyor belts.

Variable speed drives

Use of variable speed drives to minimize energy use, component wear and improved performance.

Bearing temperature and vibration monitoring

Sizers use smart machine technology to monitor components to predict maintenance requirements. Get ahead of servicing needs and minimize downtime.

Replaceable teeth

Wear segments have replaceable teeth that allow customers to swap them out for renewed performance. Extends machine life and lowers costs compared to conventional “throwaway” designs.

Specifications

- Full specs

- Application: Bauxite, phosphate, shale, coal, limestone, nickel, gold, copper, coke, borax, polyhalite, and gypsum

- Capacity (TPH): Up to 1,000

- Capacity (MTPH): Up to 1 000

- Mass (tons): 14.3 - 18.7

- Mass (tonnes): 13 - 17

- Roll spacing (in): 23.6

- Roll spacing (mm): 600

- Feed size (in): Less than 10

- Feed size (mm): Less than 250

- Standard output product sizes (mm): 25, 38 or 50

- Standard output product sizes (in): 1, 1.5 or 2

- Roll length range (in): 39.4 - 98.4

- Roll length range (mm): 1 000 - 2 500

Support you can count on

Find what works for you