1 min read

Good to excellence: How collaboration and Smart Solutions drove record-breaking results at Khutala Colliery

- Overview

- Challenge

- Solution

- Results

- Conclusion

Select continent

Meeting the moment in a changing industry

The mining industry is undergoing rapid transformation. Commitment to continuous safety improvements, growing cost pressures, and the need for greater operational efficiency require mining operations to rethink how they work.

At Komatsu, we are meeting this challenge by focusing on collaboration, driving innovation, and keeping results at the center of everything we do. Through our Smart Solutions, we’re helping customers navigate change and turn their toughest challenges into performance breakthroughs.

One standout example is our collaboration with Seriti’s Khutala Colliery.

Rebuild, reboot: Setting the stage

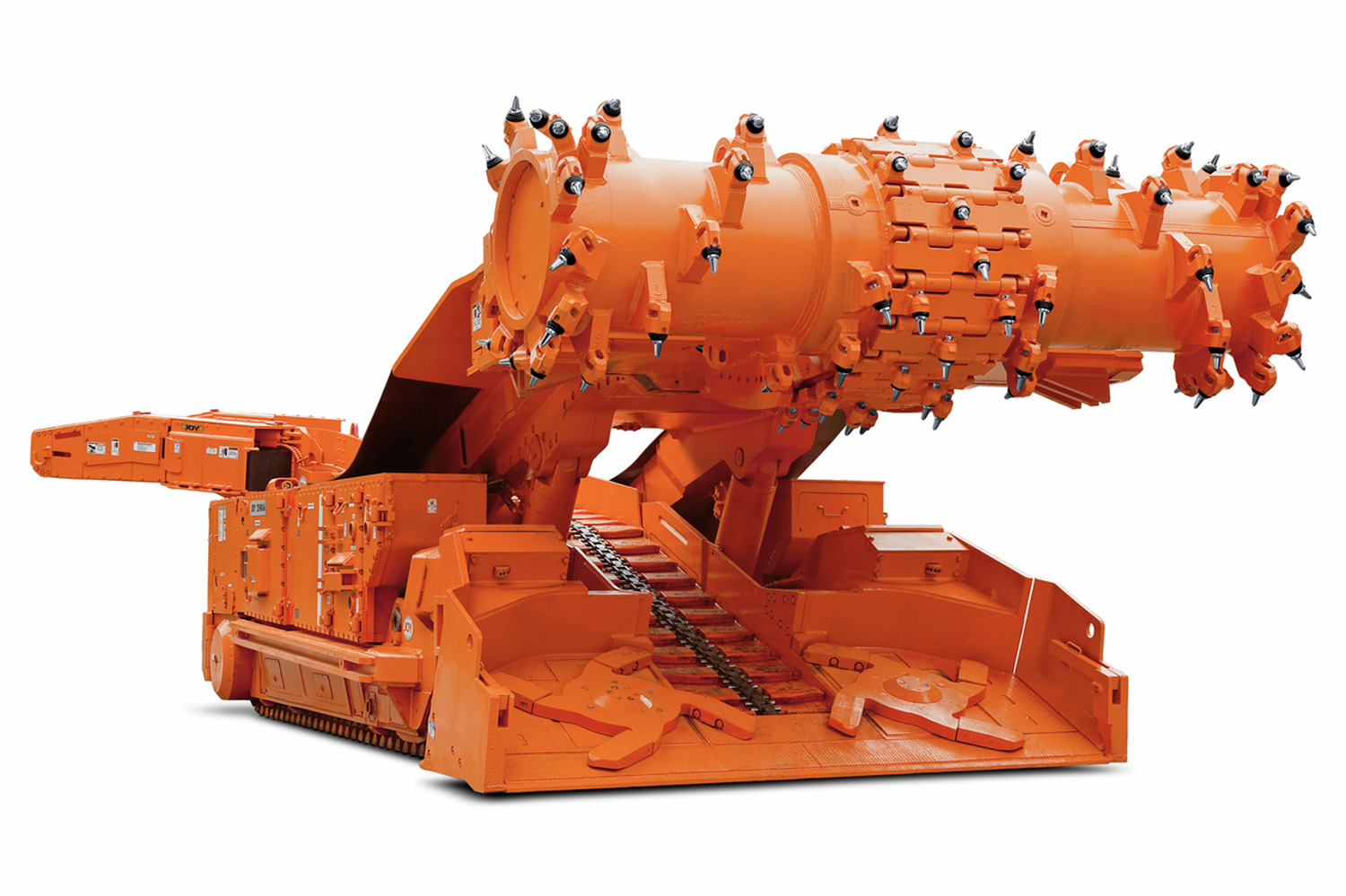

In 2022, Khutala made a strategic decision to send its Joy 12HM31B Continuous Miner to Komatsu for a condition-based rebuild. With performance declining and reliability issues mounting due to the natural wear and aging of the machine, Khutala's maintenance team saw that a simple repair wouldn’t be enough. They needed a deeper reset—one that would ensure sustainable uptime and set the groundwork for more ambitious production targets. Our ability to deliver not just a rebuild, but a full performance restoration that supports our customers’ broader goals, made us the trusted choice.

Launching the “Good to Excellence” campaign

In April 2023, Komatsu launched the Good to Excellence campaign, a customer-focused program designed to maximize impact through deeper site engagement, combined expertise, and data-driven action. The goal was simple but powerful: to help our customers transition from good operations to truly excellent ones. Smart Solutions leverages real-time data from machines to enable mine management to make business driven decisions based on analytics and data analysis.

At Khutala, the initiative gained immediate traction. The previous General Manager, Raymond Makgota (now Chief Operating Officer, Seriti Mining), recognized the potential and committed to the program, setting the tone for cross-team collaboration.

Building the blueprint for excellence

The campaign began by identifying the “critical few” success factors. Two stood out:

- Technical skills upliftment

- Equipment operational awareness

Armed with Smart Solutions and a dedicated Komatsu support team, mine management adopted a custom strategy for Khutala. Key milestones included:

- Creating an engagement model to ensure consistent collaboration

- Appointing dedicated champions to coordinate efforts

- Defining short- and long-term KPIs to track progress and drive accountability

Measurable milestones, record results

During 2023, the Good to Excellence campaign gained good momentum and by early 2024, the impact of the collaboration was undeniable. On 15 March 2024, the iThembalethu section at Khutala hit a historic milestone, 1 million tonnes of production, followed by the Insele section on 25 March 2024. It was the first time in more than a decade that any section had reached this level of production.

When the baton was passed to the new General Manager, Mr. Mhlonipheni Buthelezi, he inherited a solid foundation - and the momentum only grew from there. Over the course of 2024, five additional sections joined the “millionaire” ranks, a clear testament to the transformation underway at Khutala Colliery.

A collaboration leveraging Smart Solutions

The success at Khutala Colliery is a model of what can be achieved when innovation meets execution. With Smart Solutions at the core, and strong data driven decisions, the Good to Excellence campaign proved that operational excellence isn’t a slogan, it’s a repeatable, measurable outcome.

With memorable records achieved by its top-performing sections, the mine’s focus shifted to elevating its most challenging areas.

This is where the "Good to Great" approach comes into play. By identifying and understanding the unique challenges and limitations within these sections, the mine began the transformation process, turning these underperforming sections into high-performing units. While these sections may not be record-breaking yet, with the right focus and strategy, excellence is within reach.

Leveraging the same proven strategies, resources, and recommendations that led to previous successes, Komatsu will gather and analyze machine data to uncover key insights to be used by the mine to develop and implement tailored solutions designed to address specific needs - and monitor progress and refine approaches to ensure sustainable improvement.

Experience has shown that this targeted, strategic approach should significantly enhance the overall performance of these Khutala Colliery sections, driving them steadily toward success.

Millionaire trophies to be presented to all five sections at Khutala Colliery

Millionaire trophies to be presented to all five sections at Khutala Colliery