Electric rope shovels

4100C BOSS

- Nominal payload (metric tons) 90.7

- Nominal payload (short tons) 100

- Dipper capacity (m^3) 49

- Dipper capacity (yd^3) 64

- Production (MTPH) 6 830 - 8 707

- Production (TPH) 7,198 - 9,598

High productivity for softer surfaces

If you’re looking for high productivity in environments that need low ground-bearing pressure, the 4100C BOSS is designed for softer operating surfaces. Built for double-side loading, this machine has extra reach and clearance for maximum load capacity.

- Low ground bearing pressure compared to similar class loading tool

- Calculations show 64-71% less emissions compared to hydraulic shovels on a pounds of CO2/tonne mined basis

Resources

Features and benefits

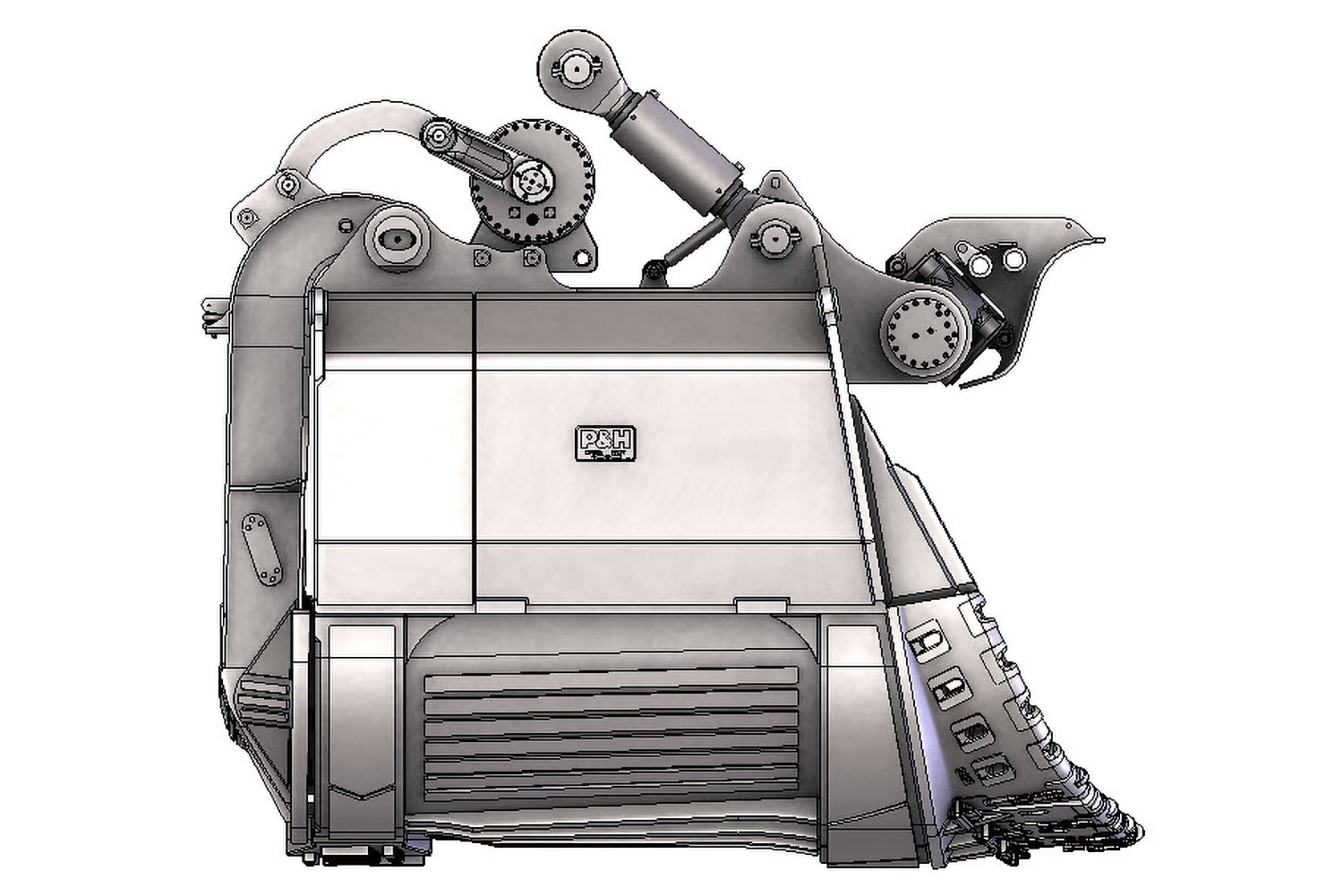

Twin leg handle

Engage the hardest of materials and easily focus on penetrating the bank with the time-tested P&H twin leg handle, instead of wasting energy twisting or rotating the dipper.

Delta style undercarriage

Minimize maintenance with a proven shoe and tumbler that requires minimal intervention and allows for operation in a loose track configuration.

TRC series dipper

One of the hardest working pieces on your shovel, the 4100C BOSS features the latest in dipper technology with a low maintenance latching system, optimal toe penetration digging and ability to pass match shovels with trucks.

Specifications

- Full specs

- Nominal dipper capacity* (yd^3): 64.0 (SAE struck)

- Nominal dipper capacity* (m^3): 49 (SAE struck)

- Rated suspended load (st): 192

- Rated suspended load (mt): 174

- Optimum truck size (360 mt (400 st) truck shown) (st): 190 - 400

- Optimum truck size (360 mt (400 st) truck shown) (mt): 172 - 363

- Nominal payload dipper capacity note: *Payload and dipper capacity are dependent on many factors. Contact Komatsu Mining for an analysis of your specific application.

- Height of cut (ft): 55 ft. 4 in

- Height of cut (m): 16.9

- Radius of cut (ft): 80 ft. 11 in

- Radius of cut (m): 24.7

- Dumping height* door open (ft): 31 ft. 0 in

- Dumping height* door open (m): 9.5

- Floor level radius (m): 16.3

- Floor level radius (ft): 53 ft. 5 in

- Tail swing radius (m): 11.6

- Tail swing radius (ft): 38 ft. 0 in

- Operator eye level (m): 9.8

- Operator eye level (ft): 32 ft. 3 in

- Dumping height (footnote): *Height shown with bail-type dipper. Heights will be greater with bail-less or compact-bail dippers. Actual dumping height can be greater than door clearance height.

- Crowd: Powerband V-belt drive between motor and gear case absorbs shock loads. First and second reduction gearing in enclosed gear case for reliable splash lubrication, ease of maintenance, and extended component life. Twin-leg dipper handle with torsion box and rack and pinion drive has inherent stability in the bank for optimal digging. Spring-set air release disc brake.

- Swing: Two modular P&H planetary gear cases of proven design and a single piece forged swing gear transmit torque for fast cycle times. Spring-set air release disc brakes – one per motor. Splash lube filtration system.

- Supply voltage: 7,200 or 13,800 V 3 Phase, 60 Hz or 6,000, 6,600, 7,200 or 11,000 Hz, 3 Phase, 50 Hz

- Supply transformer: Minimum 3,300 kVA

- Minimum short circuit VA available at shovel: 25 MVA

- Supply voltage note: *Voltage per customer requirements

- Propel: Propel on demand provides rapid transfer to propel mode. Rapid transfers allow frequent positioning of the shovel to the bank resulting in faster cycle times and more efficient digging. Two rugged P&H planetary gear cases of proven design independently transmit torque to the drive sprockets, producing the tractive effort required for fast, efficient propel and positioning operations. P&H brand Delta drive low tension sprocket drive system with heavy duty cast crawler shoes. Spring-set air release disc brakes – one per motor.

- Hoist for gearing: All gearing housed in single enclosed gear case with filtered oil circulation for reliable splash lubrication and ease of maintenance. Large 68 in diameter hoist drum for extended rope bending life. Ferrule becket system and dual electric tuggers are standard for efficient rope change. Dual electric tugger option is available. Spring-set air release disc brakes – one per motor.