Blasthole drills

320XPC

Rotary drill

- Hole diameter (in) 10 5/8 - 17 1/12

- Hole diameter (mm) 270 - 444

- Bit loading (kg) 68 038

- Bit loading (lbs) 150,000

- Single pass hole depth (ft) 65

- Single pass hole depth (m) 19.8

Purchase options

Request a quoteThe reliability you need for the productivity you demand

Designed with the reliability and productivity you need in mind, the 320XPC blasthole drill is a robust electric-platform-style drill engineered for challenging drilling in tough rock. It has a solid record of performing in harsh conditions — arctic, high-altitude and hard rock applications. An excellent choice to help you achieve your production goals with powerful pulldown and propulsion capabilities.

- 13% more bit load on average than other drills this size*

- Performs in harsh environments — under -30 °C, over 4,500 meters or altitude`

- 68,040 kgs bit loading (150,000 lbs.), 34,040 NM torque — breakthrough power for tough rock conditions found around the world

- [FOOTNOTE]*Based on competitive analysis of advertised bit loads of leading manufacturers

Resources

Features and benefits

Powerful pulldown

Built for availability. Positive bit loading with an electric top-drive rack-and-pinion pulldown means a reduction in wearing components. This feature also offers a robust and precise way to transmit the pulldown force into the bit.

Rugged masts

Drill masts must tolerate high loads, so we used finite element analysis to achieve high-cycle fatigue-resistant structures and control downtime and costs due to repairing cracks. Constructed of standard high-strength alloy steel, the mast provides robust rotary carriage and drill string support.

Superior propulsion

Built for durability with mainframes and crawler frames that can stand up to your hard-rock mine conditions. Rugged crawlers and powerful hydrostatic propel drives deliver manoeuvrability, gradeability and fast set-ups.

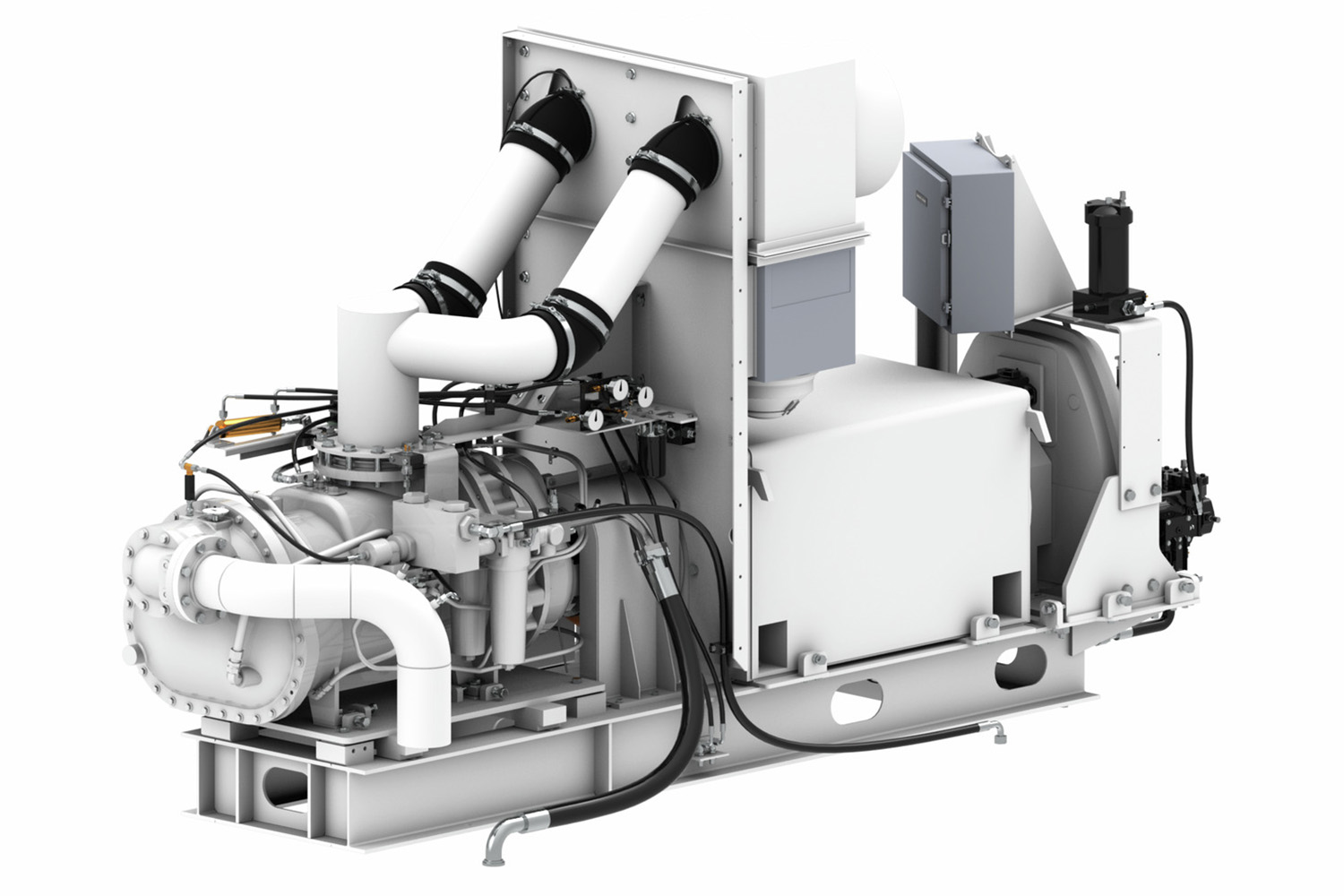

Ample, reliable air compressors

A range of dependable, mining-duty compressors are available to meet the specific bailing air needs for your mine operations. The 320XPC's compressors provide quality service.

Superior operator visibility

Operators have a wide view of drilling and surrounding areas with windows and video technology to help them maintain situational awareness while drilling and propelling. The operator's chair swivels to face the direction of travel during propelling for ease of repositioning.

Productive operator environment

Operator comfort and productivity are key in the FOPS Level II-certified structure, which features shatter-resistant glass, ergonomic controls, intuitive displays and an adjustable air seat suspension with viscous cab mounts to mitigate harsh vibrations.

Specifications

- Full specs

- Crawler type: Heavy-duty lug and tumbler drive system, Komatsu design

- Shoe/track pad width (standard)(in): 36

- Shoe/track pad width (standard)(mm): 914

- Shoe/track pad width (optional)(in): 44

- Shoe/track pad width (optional)(m): 1 117

- Propel machinery (kW): Dual hydrostatic planetary drive with sprint set, hydraulic release break, 231 kW

- Propel machinery (HP): Dual hydrostatic planetary drive with sprint set, hydraulic release break, 310 HP

- High propel speed (kph): 0 - .97 (60 Hz), 0 - 1.6 (60 Hz)

- High propel speed (mph): 0 - .8 (50 Hz), 0 - 1 (60 Hz)

- Low propel speed (kph): 0 - .80 (50 Hz), 0 - 1.28 (50 Hz)

- Low propel speed (mph): 0 - .5 (50 Hz), 0 - .6 (60 Hz)

- Maximum grade (%): 20%

- Take-up adjustment: Jack and shim

- Air system type: Sullair oil-flooded screw

- Air system filter type: Dual Donaldson 2-stage, dry type (Gardner Denver), three Donaldson 2-stage, dry type (Sullair)

- Standard output (CFM): 3,450*

- Compressor type: Gardner-Denver SSY Series oil-flood screw type

- Operating pressure (psi): 65

- Operating pressure (kPa): 448

- Air system disclaimer: *Nominal air volume. Actual values may vary according to application. Requires: 1,000 HP main motor

- Climate control: Mine air systems HVAC unit available providing pressurization and filtration

- Controls: PLC controlled, back lit for night operation

- Falling objection protection: FOPS level II

- Glazing: Shatter-resistant, laminated glass on all sides, roof window with guard

- Noise: <80 dB while driving

- Operator cab type: Rear mounted with vibration and noise suppression

- Pipe handling type: Parallelogram style pipe rack, one rack is standard

- Pipe diameter (in): 9.25 - 13.625

- Pipe diameter (mm): 235 - 346

- Pipe handling options: Additional pipe rack, up to two total

- Auxiliary equipment: Standard deck wrench

- Auxiliary winch (lbs): 14,000

- Auxiliary winch (kg): 6 350

- Breakout wrench: P&H brand SureWrench

- Mast construction: Lattice type using alloy steel structural shapes

- Mast (m): Standard: 19.81, Optional: 21.3

- Mast (ft): Standard: 65, Optional: 70

- Raising and lowering (mm): Two hydraulic cylinders standard diameter: 267

- Raising and lowering (in): Two hydraulic cylinders standard diameter: 10.5

- Electrical system features: Minimum 1.5MVA continuous, 6MVA minimum short circuit at drill

- High voltage switchgear: External disconnect at trail cable junction box, high voltage load break disconnect and high voltage vacuum contactor for main drive motor and drives

- Incoming power supply voltage (V): 60 Hz: 4 160 V/7 200 3-phase, 50 Hz: 6 600 V or 7 200 V 3-phase

- Main drive motor (standard)(kW): 522

- Main drive motor (standard)(HP): 700

- Main drive motor (optional)(HP): 1,000

- Main drive motor (optional)(kW): 746

- Maximum single pass (ft): 65

- Maximum single pass (m): 19.8

- Maximum single pass (optional)(m): 21.3

- Maximum single pass (optional) (ft): 70

- Maximum single pass (standard) (m): 19.8

- Maximum single pass (standard) (ft): 65

- Maximum multi-pass (Single pipe rack)(m): 39.6

- Maximum multi-pass (Single pipe rack) (ft): 130

- Maximum multi-pass (Dual pipe rack)(m): 59.4

- Maximum multi-pass (Dual pipe rack) (ft): 195

- Maximum bit loading (kg): 68 083

- Maximum bit loading (lbs): 150,000

- Rotary machinery design: Dual DC P&H electric motors, independent ABB DCS 880 drives control (master/follower drive topology), can be run as single rotary motor during service/repairs

- Rotation speed (rpm): 0 to 119

- Maximum torque (N-m): Up to 33 895

- Maximum torque (ft-lbs): Up to 25,000

- Operating weight (maximum)(kg): 181 437

- Operating weight (maximum)(lbs): 400,000

- Cylinders (mm): Four (4) 254 mm diameter x 1 676 mm stroke

- Cylinders (in): Four (4) 10 in diameter x 66 in stroke

- Auto level: Standard feature

-

Jack pads (optional)

- Diameter (optional)(in): 50

- Diameter (optional)(mm): 1 270

- Ground pressure (optional)(psi): 46

- Ground pressure (optional)(kPa): 317

-

Jack pads (standard)

- Diameter (standard)(in): 30

- Diameter (standard)(mm): 762

- Ground pressure (standard)(psi): 129

- Ground pressure (standard)(kPa): 840

- Hoist pulldown design: DC electric motor driven chainless rack and pinion design

- Drill feed (ft/min): Up to 16

- Drill feed (m/min): Up to 4.9

- Hoist (ft/min): Up to 105

- Hoist (m/min): Up to 37.0

- Auxiliary system: Open loop design utilizing vane pumps for mast raising, machine leveling, and pipe handling

- Control valve: Manifold mounted electro-hydraulic, PLC controlled - Discrete 24VDC Solenoid

- Filtration: 3-micron return filters, 5-micron high pressure filters, 3-micron charge filters, magnetic suction strainers

- Hydraulic lines: Extensive use of high pressure steel tubing

- Main system: Closed loop design utilizing dual variable-displacement piston pumps for propel

- Lighting features: Standard: LED floodlights for work area lighting

- Shipping weight with masts (kg): 153 949

- Shipping weight with masts (lbs): 339,400

- Ground bearing pressure for track pads with 1 117 mm shoes (kPa): 156

- Ground bearing pressure for track pads with 36 in shoes (psi): 29.0

- Ground bearing pressure for track pads with 914 mm shoes (kPa): 200

- Ground bearing pressure for track pads with 44 in shoes(psi): 22.6

- Electrical control features: Centurion supervisory controller provides direct integrated communication with motor drives giving precise motor control. Real-time multi-tasking capability allows for optimal machine logic sequencing, monitoring and control. Centurion I/O system uses ‘Profibus’ communication protocol for seamless integration of all drill subsystems and future expandability. Low-voltage 24VDC I/O drop points feature open and short circuit detection for improved diagnostics and troubleshooting. Centurion information system’s enhanced graphical user interface (GUI) features intuitive, icon-based screens to display vital information such as drill status, troubleshooting information, and production drill monitoring data. System is PreVail RHM-ready and comes with a one year free subscription to PreVail RHM.