Wheel loaders

WE1350

Surface mining wheel loaders

- Horsepower (HP) 1,676

- Horsepower (kW) 1 250

- Bucket capacity (m^3) 22.94

- Bucket capacity (yd^3) 30

- Operating weight (kg) 194 228

- Operating weight (lbs) 428,000

Purchase options

Request a quoteMake your operation its most productive

When your goal is maximizing your mining operation's productivity, it's all about cost per ton. The versatile WE1350 is engineered to improve both sides of the equation: low cycle times and utmost reliability to boost your tonnage, multiple features designed to minimize your fuel and maintenance costs.

- Up to a 45% fuel consumption reduction*

- 35% CO2 reduction*

- Up to a 10-15% TCO advantage*

Note: *compared to mechanical loaders or HEX machines

Features and benefits

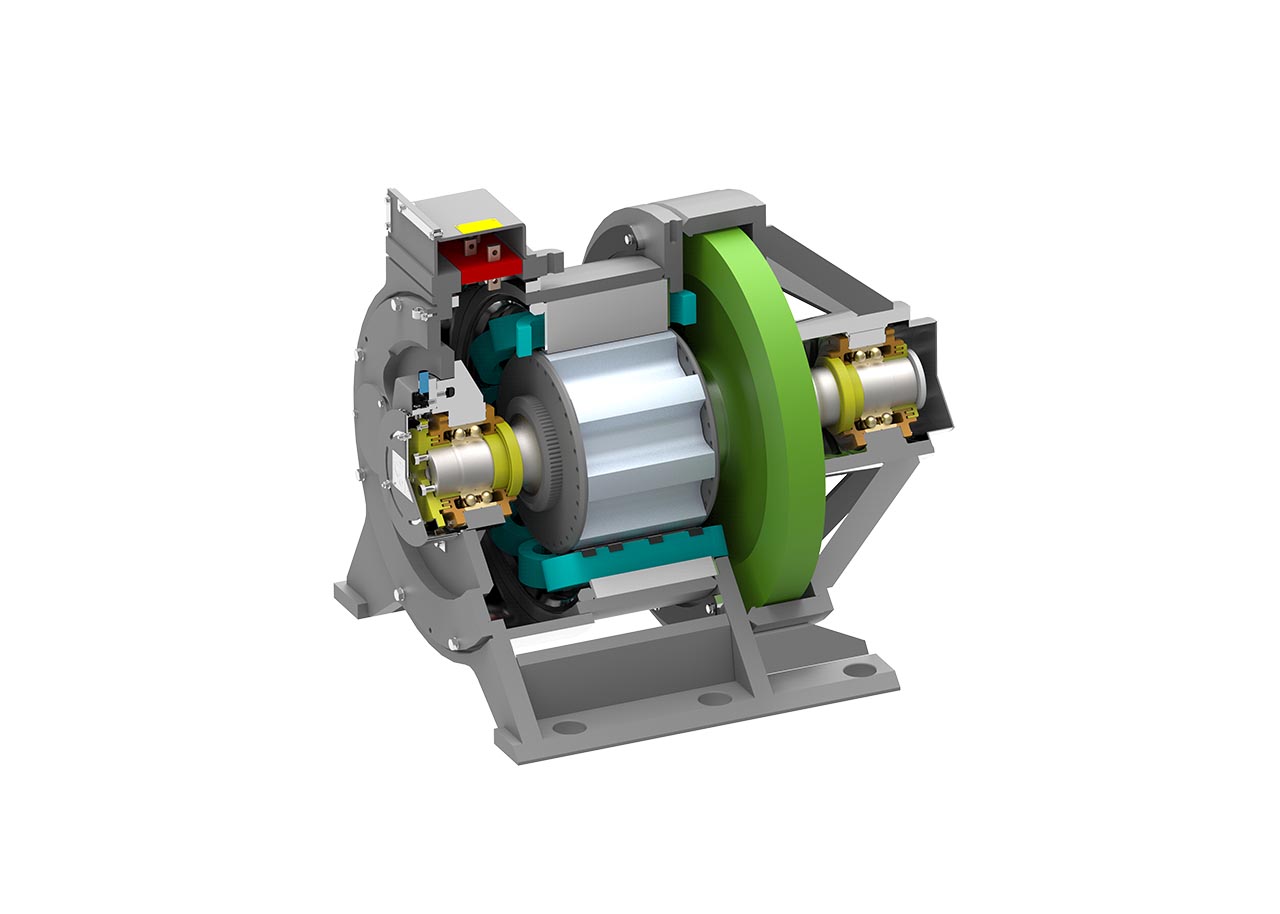

Fuel efficient SR Hybrid Drive

The SR Hybrid Drive system is fully regenerative. During braking or retarding, electrical motors become generators and feed power back into the electrical system. This allows for up to 45% less fuel consumption than comparably sized mechanical drive wheel loaders.

Peak power on demand

The Kinetic Energy Storage System (KESS) works in concert with the SR Hybrid Drive to store significant horsepower captured from braking and direct it to supplement peak power demand. The result is fast cycle times for more tons per gallon/liter used or CO2 emitted.

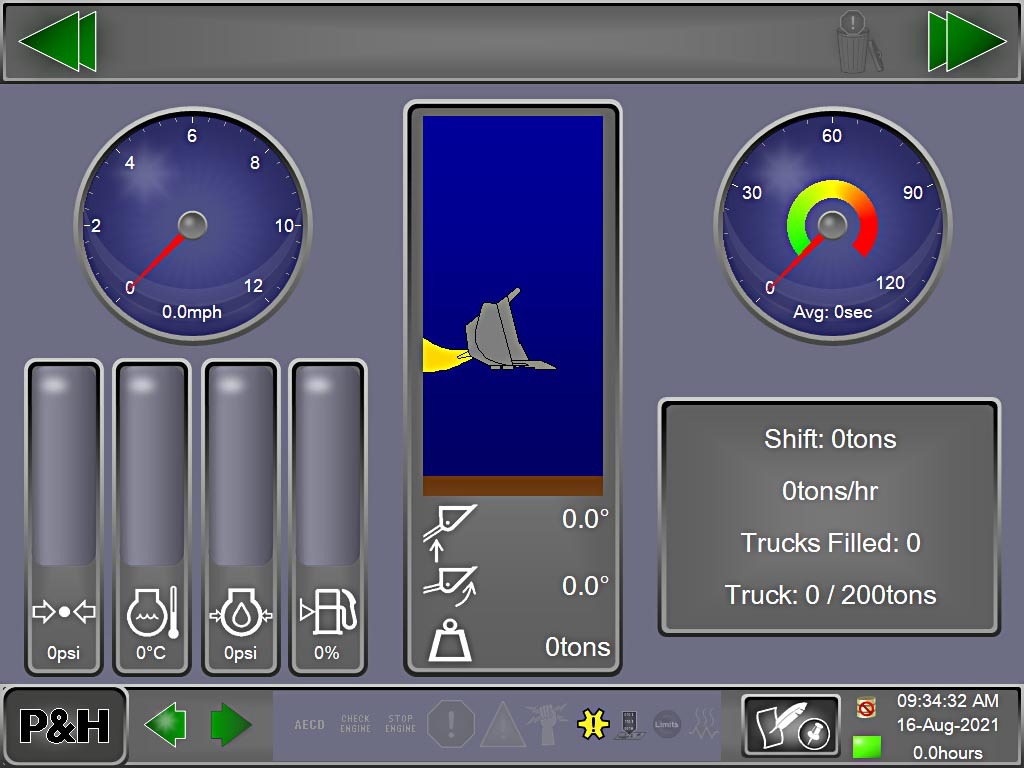

Peak power controls that support operator efficiency on demand

The LINCS II network control system provides instant, real-time feedback and vital statistics, such as bucket height and angle, individual bucket payload, and total tons moved. All of it helps your operators maximize productivity by adjusting to conditions.

Attuned to operator comfort

The spacious, environmentally controlled cab offers great visibility, a comfortable ride and room for a trainer seat. Digital joysticks give your operators easy and responsive control, while the highly adjustable, heated/cooled seat helps minimize driver discomfort.

Fast, efficient maintenance

Multiple design features help keep your maintenance costs low: the integrated, patented drive system has few components resulting in longer maintenance intervals, multiple access points mean faster component change-out times and more uptime for your machine.

Handles multiple site duties

If your operation involves frequent equipment relocations, you’ll love this loader. It can keep the pit floor clean and level without support equipment, offers outstanding mobility and travel speed, and handles berm maintenance, road repair and cutting ramps.

Specifications

- Full specs

-

Standard lift

- Operating payload of standard lift (kg): 40 823

- Operating payload of standard lift (lbs): 90,000

- Straight standard lift (kg): 108 776

- Straight standard lift (lbs): 239,809

- Full 45 degree turn standard (kg): 98 849

- Full 45 degree turn standard (lbs): 217,925

- Breakout force standard (kN): 978

- Breakout force standard (lbs): 219,772

- Operating weight standard (kg): 194 228

- Operating weight standard (lbs): 428,200

-

High lift

- Bucket capacity high lift (yd^3): 28

- Bucket capacity high (m^3): 21.41

- Operating payload of high lift (kg): 38 102

- Operating payload of high lift (lbs): 90,000

- Straight high lift (kg): 100 068

- Straight high lift (lbs): 239,809

- Full 45 degree turn high (kg): 90 936

- Full 45 degree turn high (lbs): 217,925

- Breakout force high (lbs): 225,687

- Breakout force high (kN): 1,004

- Operating weight high (kg): 196 496

- Operating weight high (lbs): 433,200

- Cummins (L): 216

- Cummins (gal): 57

- Detroit (L): 330

- Detroit (gal): 87

- Engine Cooling (gal): 101

- Engine Cooling (L): 382

- Fuel (US gal): 925

- Fuel (L): 3 501

- Gearbox (gal): 7

- Gearbox (L): 27

- Hydraulic (gal): 375

- Hydraulic (L): 1 419

- Planetaries each (L): 136

- Planetaries each (gal): 36

- SR converter cooling (gal): 31

- SR converter cooling (L): 117

- Pumps details: Maximum flow rate at 1,800 rpm

- Main Piston (4) (gpm): 371

- Main Piston (4) (L/min): 1 404

- Steering piston (gpm): 89

- Steering piston (L/min): 342

- Fan/blower drive tandem piston (gpm): 45/45

- Fan/blower drive tandem piston (L/min): 171/171

- Accessory piston (gpm): 21

- Accessory piston (L/min): 81

- Cooling system circulating pump vane (gpm): 108

- Cooling system circulating pump vane (L/min): 409

- HPD drive box: Pressurized, cooled, and filtered lubrication; ratio 1:1

- Cylinders: Double-acting, single-stage (diameter and stroke), (standard and high fit)

- Cylinders hoist (in): 13.5 x 74.5

- Cylinders hoist (mm): 343 x 1 892

- Cylinders bucket (in): 10 x 41.5

- Cylinders bucket (mm): 254 x 1 054

- Cylinders steering (in): 7.5 x 30

- Cylinders steering (mm): 190 x 762

-

Cylinders

- Hoist (in): 13.5 x 74.5

- Hoist (mm): 343 x 1 892

- Bucket (mm): 254 x 1054

- Bucket (in): 10 x 41.5

- Steering (in): 7.5 x 30

- Steering (mm): 190 x 762

-

Valves

- Valves main (3) (L/min): 700

- Valves main (3) (gpm): 185

- Valves steering (1) (gpm): 90

- Valves steering (1) (L/min): 341

- Pump pressure (psi): 4,000 (main valve), 3,400 (steering valve)

- Pump pressure (kPa): 27 980 (main valve), 23 443 (steering valve)

- Truck match (ton): 200-260

- Truck match (tonne): 181-236

-

Payload

- Standard (lbs): 90,000

- Standard (kg): 40 823

- High lift (lbs): 84,000

- High lift (kg): 38 102

-

Engine

- Engine (kW): 1 249

- Engine (HP): 1,676

- KESS (kW): 820

- KESS (HP): 1,100

- Primary brake system type: Electric dynamic braking system is controlled from the accelerator pedal and can bring the loader to a full stop without application of mechanical brakes.

- Secondary brake system type: Air modulated traction motor speed disc brakes. Single disc and caliper on each traction motor (4). Emergency fail safe brakes are spring applied in the event of air pressure loss.

- Parking brake system type: Spring applied, air release traction motor speed disc brakes.

-

Diesel power options

- MTU detroit diesel engine: Tier one

- Detroit Model: 12V Series 4000 12 cylinders

- Detroit Type: 4-cycle turbocharged

- Rated power Detroit: 1,600 HP @ 1,800 rpm

- Independent power module mounting system: Consisting of the engine coupled to the SR generator, is cradled within the rear frame by a three-point isolation system.

- Radiator/oil cooler module: Replaceable tube type, side-by-side split flow. Thermostatically controlled, variable speed hydraulic motor-driven, radiator-mounted fan. Auxiliary oil cooler available for high ambient conditions.

- Exhaust system type: Dual, low restriction mufflers with vertical, mid-hood discharge

- Model Tier 1,2 (V): 12V Series 4000, 12 cylinders

- Rated power (kW): 1 193 kW @ 1 800 rpm

- Cummins Diesel engine tier type: Tier 2

- Cummins Model: QSK 50, 16 cylinders

- Cummins Type: 4-cycle turbocharged

- Cummins Rated power (kW): 1 193 kW @ 1 800 rpm

- Cummins Rated power (HP): 1,600 HP @ 1,800 rpm

- Standard, ISO-rated capacity (lbs.): 90,000

- Standard, ISO-rated capacity (kg): 40 823

- High lift, ISO-rated capacity (lbs.): 84,000

- High lift, ISO-rated capacity (kg): 38 102

- Buckets type: Rock and coal bucket configurations available. Buckets sized to material density.

- Standard iso rated capacity (lbs): 90,000

- Standard iso rated capacity (kg): 40 823

- SR hybrid drive switched reluctance (SR): Technology propulsion system

- Digital microprocessor type: Controlled traction drive

- SR hybrid drive advantages include: No commutator, brushes or rotor windings on SR motors or generator. SR KESS - Kinetic Energy Storage System. Parts commonality - power conversion modules identical for motor and generator.

- Generator specifics: G100 SR generator

- Traction motors type: B40A SR motor and SR all wheel drive (independent SR motor for each wheel)

- Planetary gearing model 51A2: In-line gear train mounted within the rim of the tire, transmitting power from the traction motor through the tire/rim assembly. A four-stage planetary drive unit in each position. Total reduction 140.8:1

-

Travel speed

- Travel speed type: Forward and reverse 0 - 19.31 kph (0 - 12 mph)

- Rims: 36 x 57 with 6 in flange

- Tires: 50/80-57 L-4

-

Hoist and bucket control

- Dump (seconds): 3

- Float (s): 5

- Hoist (seconds): 11.8

-

Steering

- High lift (ft, in): 45 ft, 2 in

- High lift (m): 13.76

- Standard lift (m): 13.5

- Standard lift (ft, in): 44 ft, 4 in

- Articulation angle (degrees): 40

- LINCS II: Microprocessor based modular design Vehicle Control Unit (VCU) with monitoring and diagnostics including integrated data logging and storage. LINCS II uses a dash mounted full color, touch screen display as the operator interface. Out-of-range conditions will cause an audible alarm along with a message screen that is color coded to indicate severity. In addition, the touch-screen display provides repair technicians with operational data and fault messages.

- LINCS II load weigh: Displays real-time load per pass, per truck and total loads. Memory capable of retaining months of production information. Capable of interfacing with radio dispatch systems for real-time monitoring.

- Structural specifics: Frames are fabricated from high strength, low-alloy steel with excellent weld characteristics and extreme low temperature properties. The front axle is an integral, fixed part of the front frame. The rear axle center oscillates 11 degrees. Unique forged ball and socket joints are utilized in multiple pivot locations (lift arms, rear axle, frame articulation, hoist cylinders). These joints are superior in absorbing and distributing multi-directional stresses. Features easily replaceable brass liners for long life and easy maintenance. High strength castings are used in key areas of fabricated structures to reduce stress and improve structural life.

- Primary: Operator cab air supply and self-cleaning replaceable filter technology. Minimum Efficiency Reporting Value (MERV) 15 efficiency level per ASHRAE 52.2-2012, 5,000 hour filter life achievable, low maintenance.

- Secondary: Dual safety filters for engine

Videos

Learn more about the comfortable and ergonomic operator’s cab in the WE series wheel loaders.

Versatility for your mine: Ultra-class wheel loaders

When planning your operation, look to wheel loaders.

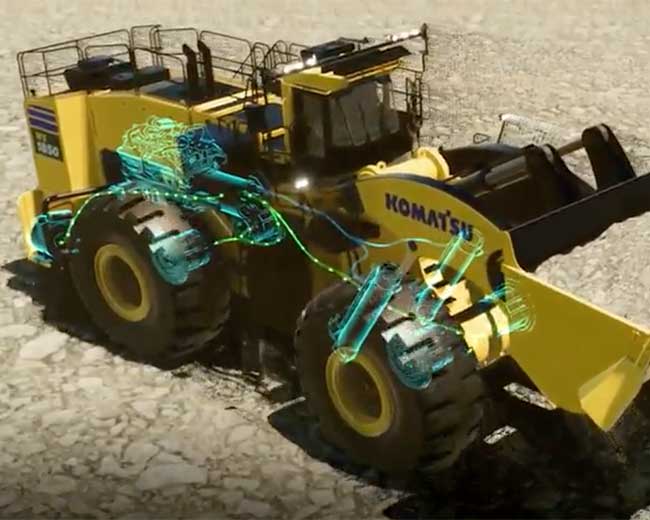

A rundown on Komatsu's WE1850 and the KESS:SR Hybrid drive system

Designed to be the workhorse of your wheel loader fleet, the versatile and flexible WE1850 features a fuel-efficient SR Hybrid Drive systems that features KESS.

- Container

- Container

- Container

Find what works for you