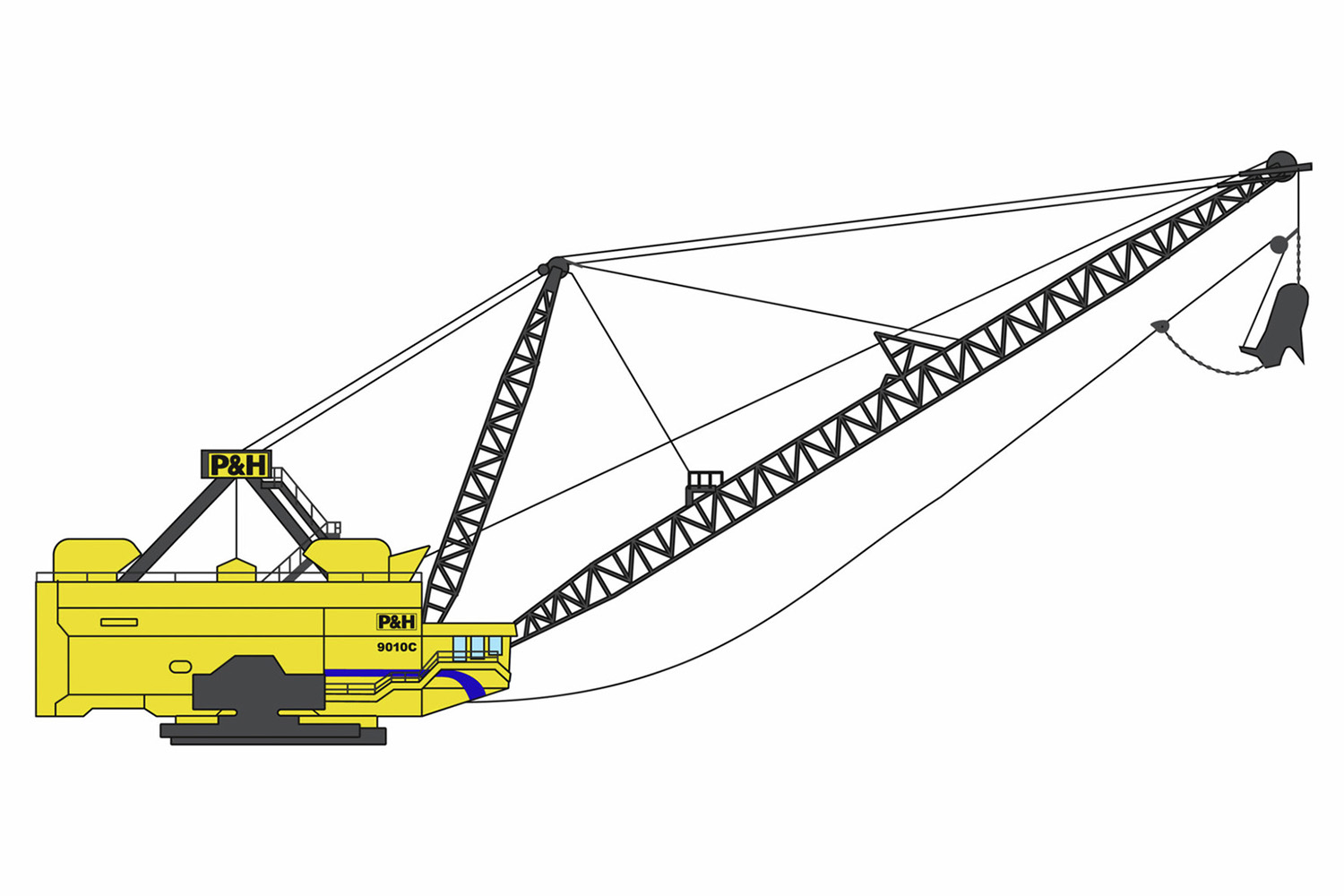

Draglines

9010C

- Bucket capacity (m^3) 42 - 60

- Bucket capacity (yd^3) 55 - 80

- Boom length (ft) 275 - 350

- Boom length (m) 84 - 107

Keep your operation humming

No matter what boom length, bucket capacity or geometry you need, you’ll find a P&H dragline built from the ground up to deliver long-term, consistent, reliable performance.

- Ultra-strong tub distributes loads evenly for outstanding reliability

- A-frame engineered to effectively manage load forces

- Four-chord boom has the structural integrity to operate in tough conditions

- Electronics platform to help operators perform at peak efficiency

Resources

Features and benefits

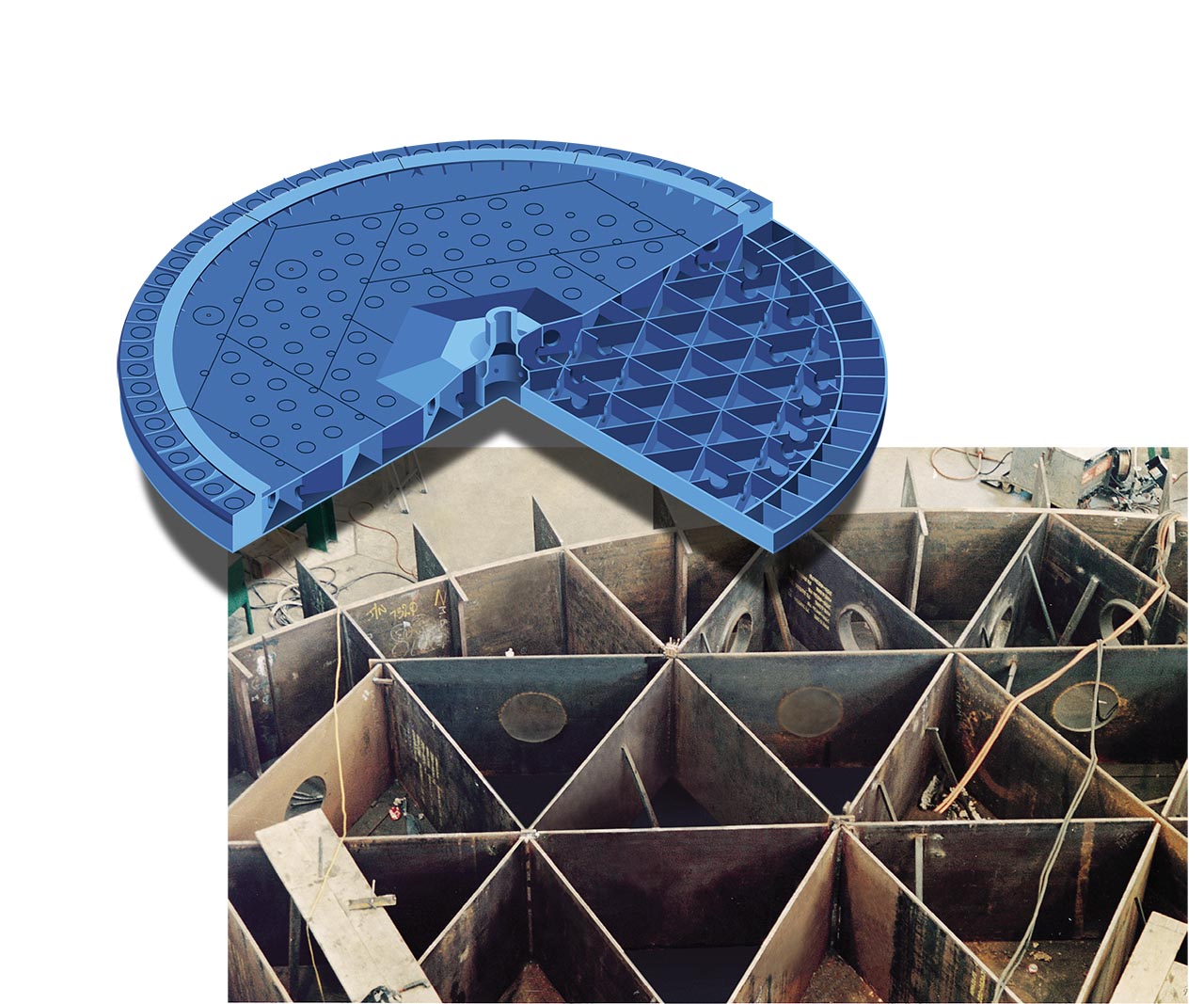

Tub engineered to perform

Built for long life and low maintenance, P&H tubs handle multi-directional loads and verti-shield welding joins on all intersection plates with one continuous weld resulting in minimal distortion with widely distributed loading and low residual stresses.

Intelligent, productivity-focused electronics

Track your machine’s performance to support efficient operation and maintenance activities. The Centurion control system utilizes smart electronics to monitor dragline operation.

Highly engineered boom and A-frame

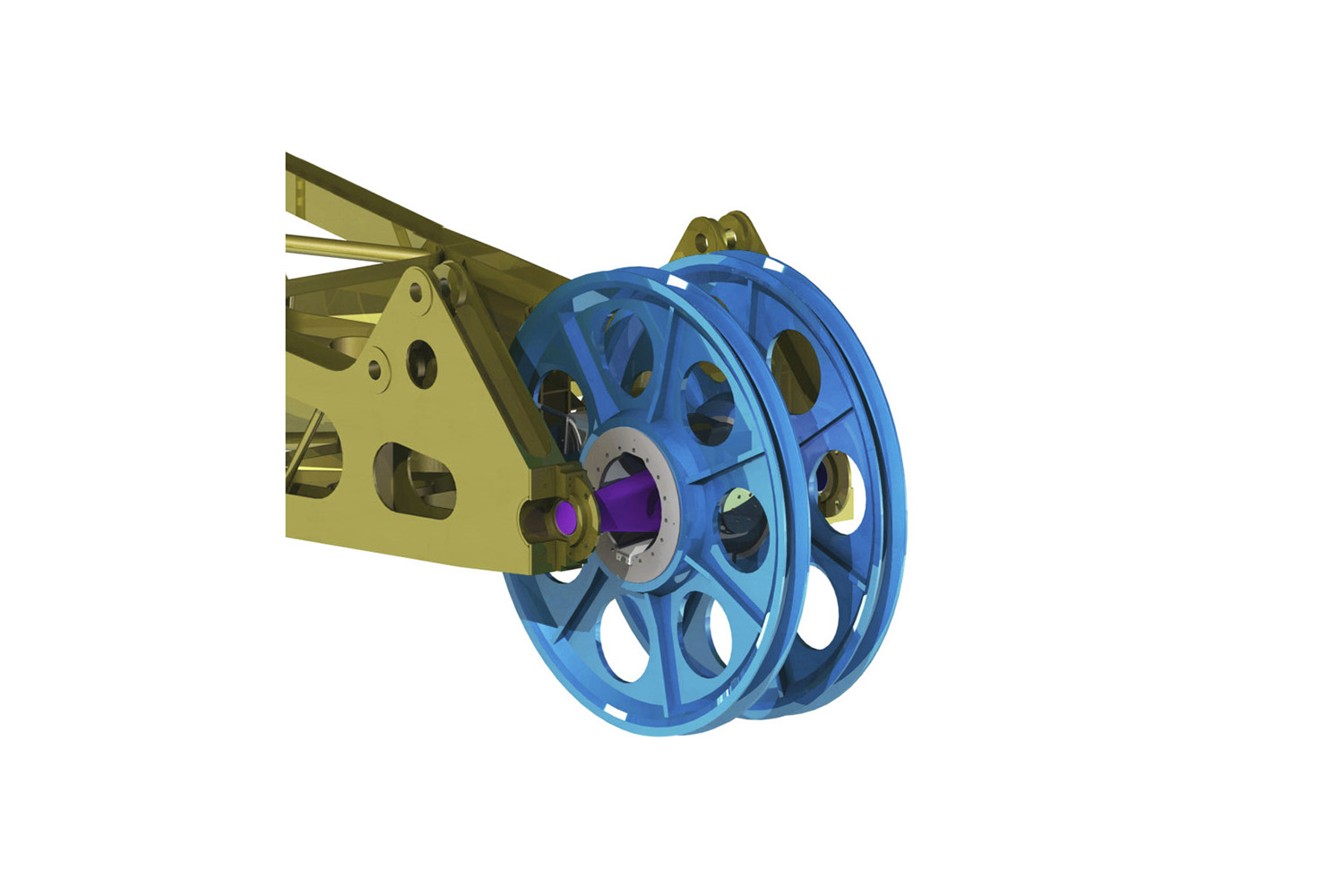

Stability, excellent visibility of boom point sheaves and balanced axial working loads with the four-chord boom with flat underside. For maximum-rated suspended load, the A-frame is engineered to keep load forces low.

Engineered with user input

Whether it’s pursuing advances in safety, delivery or solutions that improve your day-to-day maintenance and inspection activities, our goal is to help you meet your goals for increased production, reduced downtime and lower cost per unit moved.

Outstanding service

At the core of our commitment to customers is collaboration to develop innovative parts, products, consumables and systems designed to lower total cost of ownership while optimizing production.

Specifications

- Full specs

- Clearance under shoes (ft): 2 ft. 3 in

- Clearance under shoes(m): 686

- Distance from center pin to boom foot (ft): 36 ft. 11 in

- Distance from center pin to boom foot (m): 11.3

- Height of boom foot (m): 3.37

- Height of boom foot (ft): 13.3

- Normal length of step (m): 2.2

- Normal length of step (ft): 7 ft. 2 in

- Pitch diameter of point sheave (mm): 3048

- Pitch diameter of point sheave (ft): 120

- Diameter of rail circle (ft): 57

- Diameter of rail circle (m): 17.4

- Rail width (in): 14

- Rail width (mm): 356

- Quantity and diameter of rollers (in): 131 x 14

- Quantity and diameter of rollers (mm): 356

- Pitch diameter of swing rack (ft): 52 ft. 3.1875 in

- Pitch diameter of swing rack (m): 15.9

- Maximum working clearance between tub and revolving frame (m): 2

- Maximum working clearance between tub and revolving frame (ft): 6 ft. 8 in

Support you can count on

P&H draglines are built for cost-effective productivity and reliability

Advanced structural analysis, CAD modeling and high-tech gearing software have been utilized to create a dragline designed to deliver outstanding long-term cost-effective productivity and reliability.

Find what works for you