3 min read

Komatsu recognized by CDP as the “A List” with the highest rating for climate change and water

- Press release,Company,Sustainability

3 min read

May 21, 2024 -- Komatsu (President & CEO: Hiroyuki Ogawa) and its subsidiary EARTHBRAIN Co., Ltd. (President & CEO: Akinori Onodera, hereinafter referred to as "EARTHBRAIN") have jointly developed a remote control system for construction machinery called "Smart Construction Teleoperation" (hereinafter referred to as "the System"). It is now on sale at Komatsu Customer Support Co., Ltd. (President: Jun Awai) nationwide.

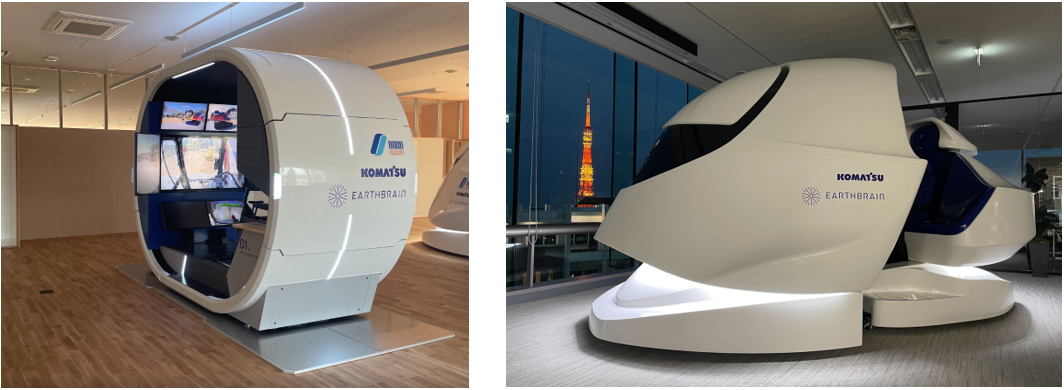

This system allows you to remotely control hydraulic excavators from a safe and comfortable environment such as an office, and in conjunction with various Smart Construction® solutions, you can remotely control the excavator while monitoring the operation of the dump truck, or switch between multiple construction machines from a single cockpit. There are two types of cockpits used for remote control, the "Intelligent Circle" type and the "Spaceship" type, and by introducing this system according to the customer's requirements, we will contribute to the realization of a safe, productive, smart, and clean future workplace.

This system has been adopted by Hirose Co., Ltd. (Representative Director: Norio Hirose, Headquarters: Niigata City, Niigata Prefecture, hereinafter referred to as "Hirose"), which operates a general construction business. Through the introduction and active use of the latest ICT-related technologies, the company aims to "renew the image of the construction industry," "reform work styles, and improve productivity," and has introduced the system as part of its promotion.

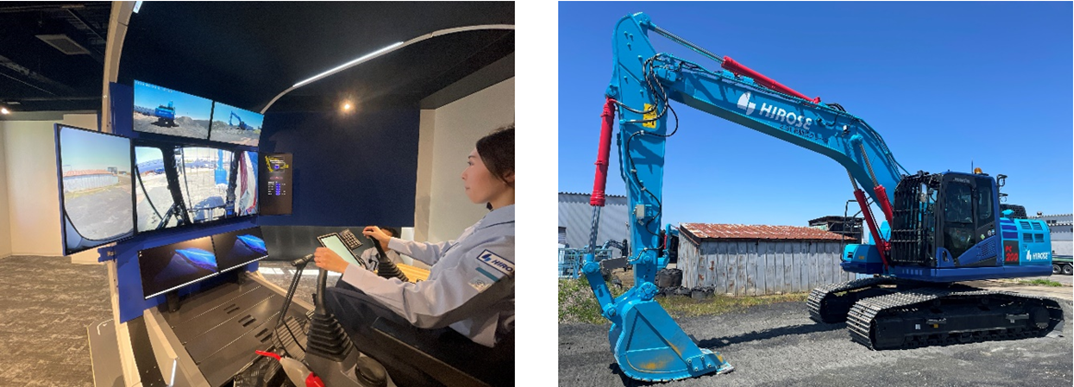

Cockpit provided to Hirose: Intelligent circle (left photo) and hydraulic excavator compatible with the system. (right photo)

Cockpit provided to Hirose: Intelligent circle (left photo) and hydraulic excavator compatible with the system. (right photo)

In 2023, Komatsu and EARTHBRAIN began on-site verification for mass production of this system with the cooperation of Ono Kaikan Co., Ltd. (Representative Director: Teruo Ohno, Headquarters: Matsuyama City, Ehime Prefecture, hereinafter referred to as "Ohno Kaikan"), and have been confirming the technical and safety aspects. In the course of this verification, we received an evaluation from Ohno Kaikan, saying, "There is little delay during remote operation, and it can be operated almost as much as when operating with an actual machine, so there is no need for the operator to go to the site, which leads to improved safety and productivity."

With the launch of this system, we will accelerate the provision of this system to even more customers. Since the conditions and environment for introducing this system differ from customer to customer, we will consider and introduce specifications that match the conditions of each customer who has made an inquiry. By providing this system to our customers, we will contribute to improving the safety and productivity of construction sites and solving issues such as labour shortages.