Mining

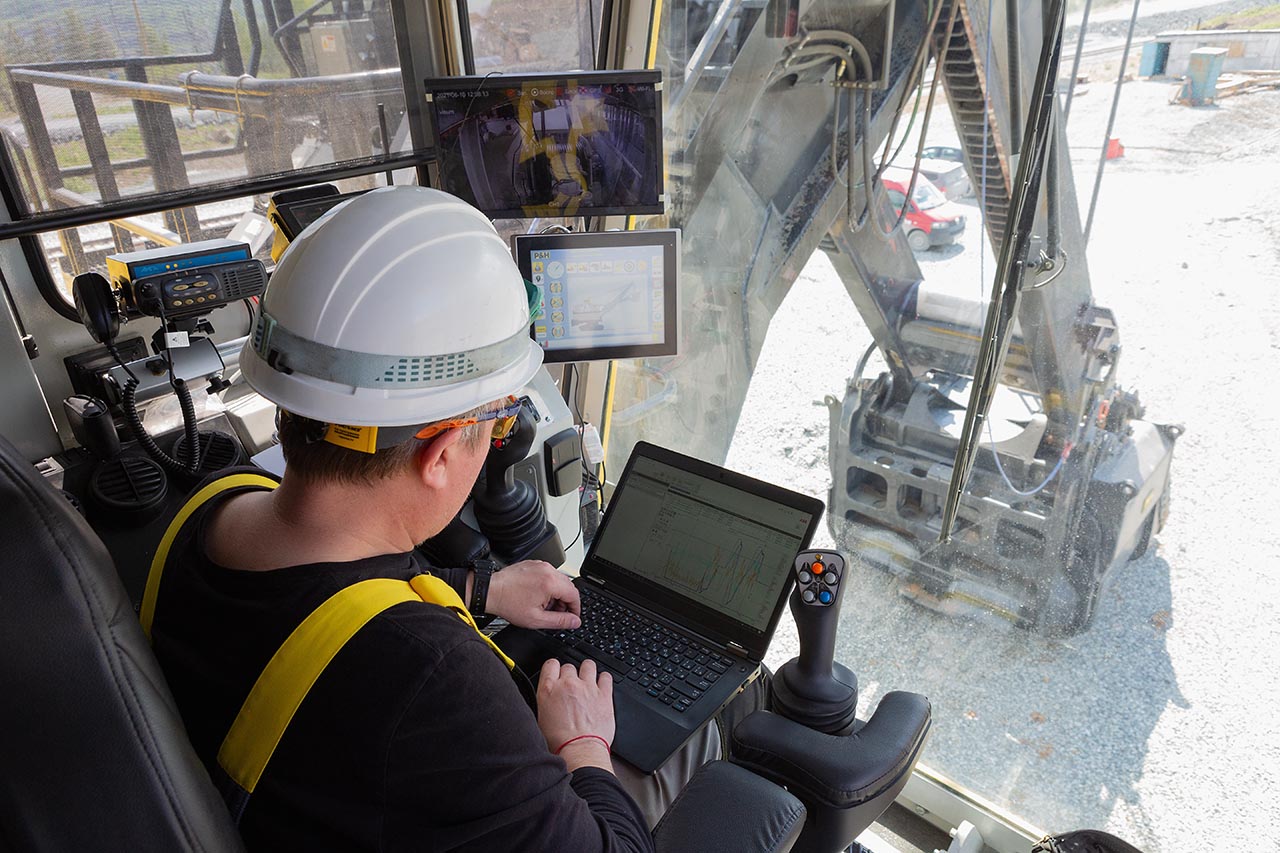

Operator assist

Our operator assist technology helps improve operator performance, comfort, and safety through automated processes or controls.

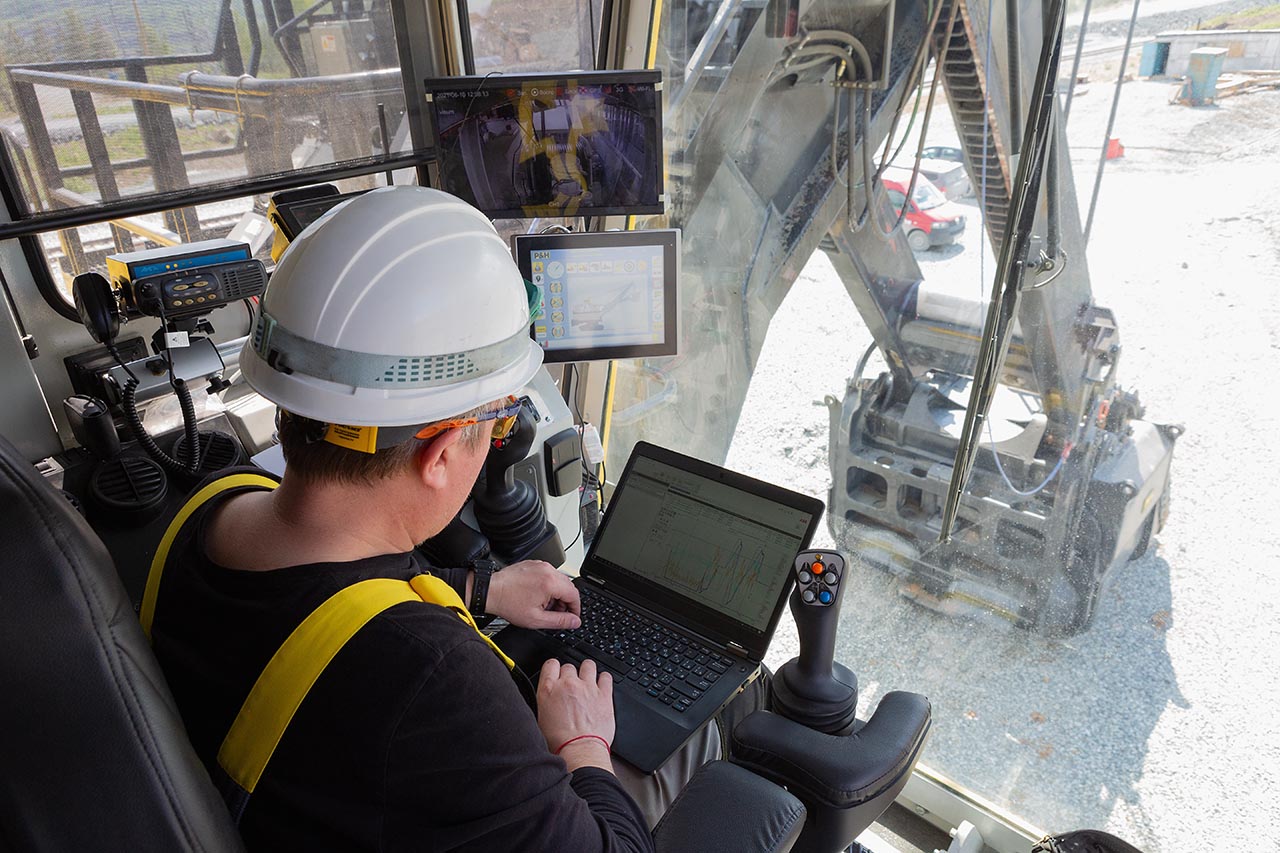

Support for your job site

Mining

Our operator assist technology helps improve operator performance, comfort, and safety through automated processes or controls.

Support for your job site