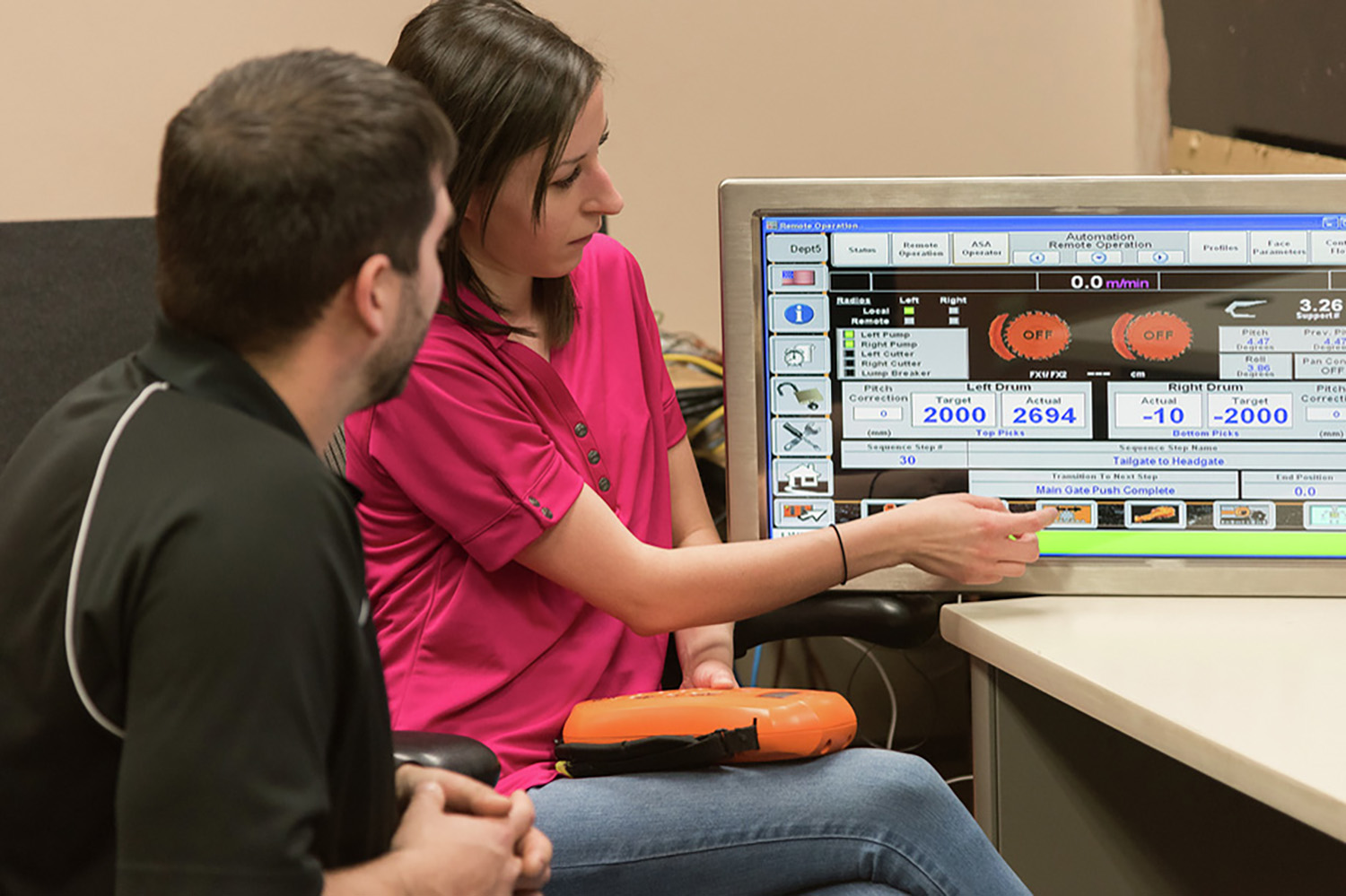

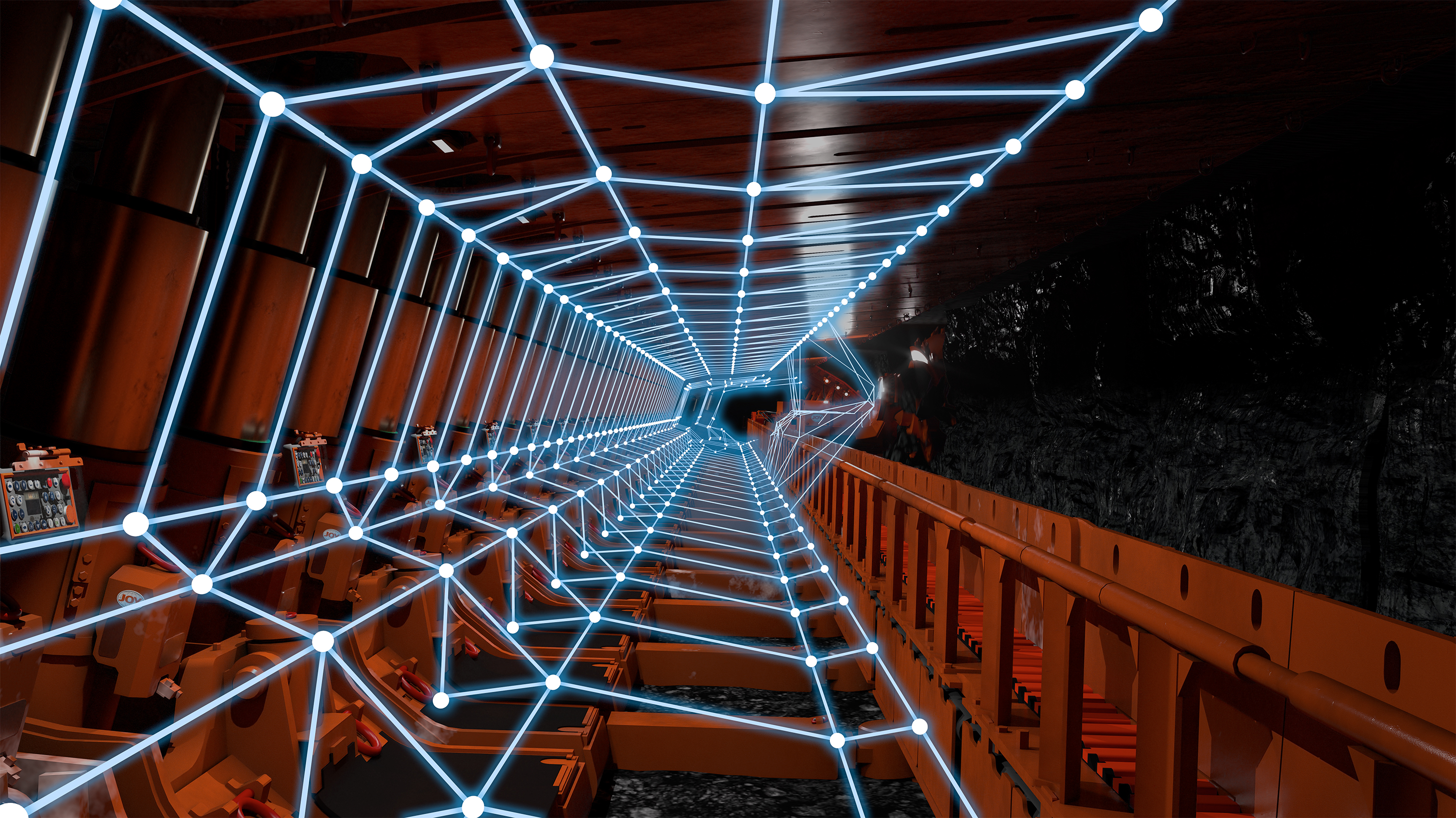

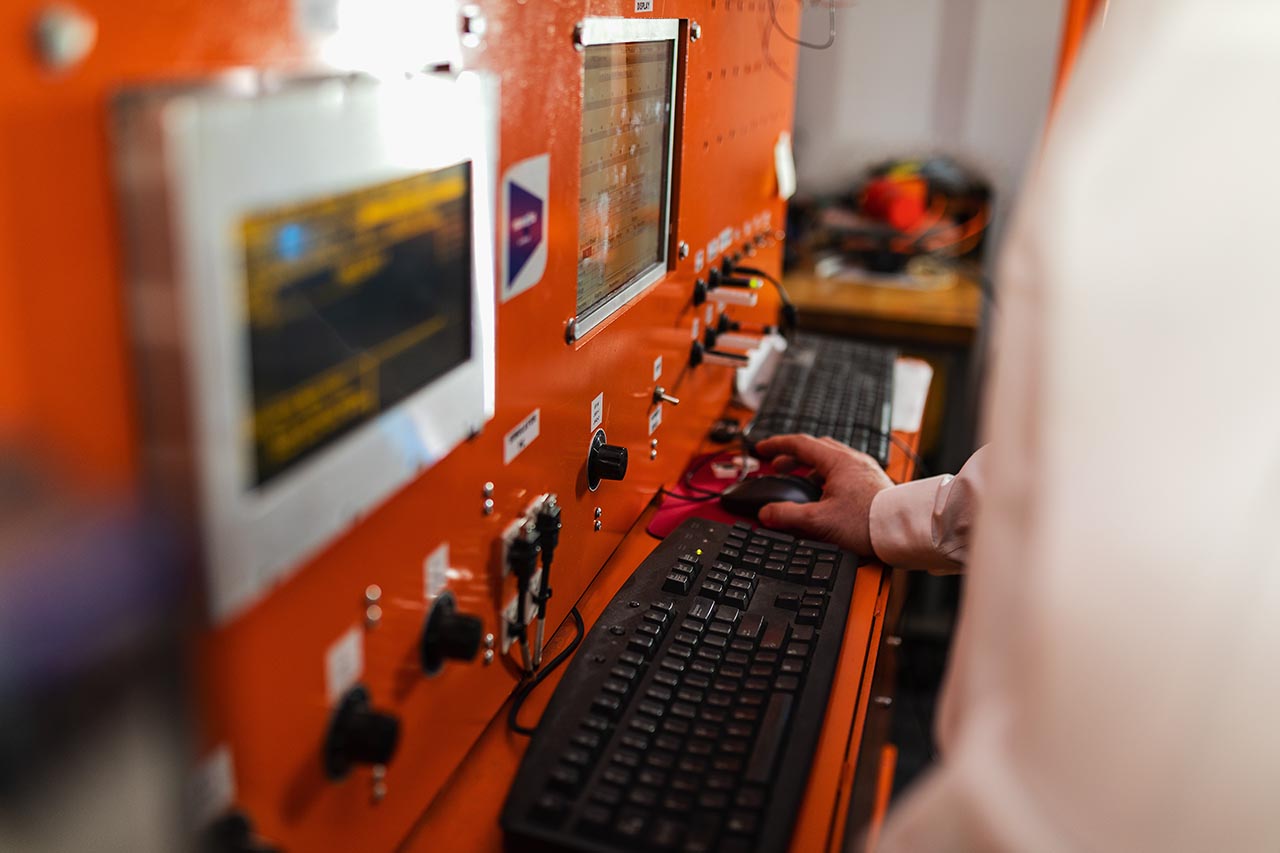

Automated Cutting sequences

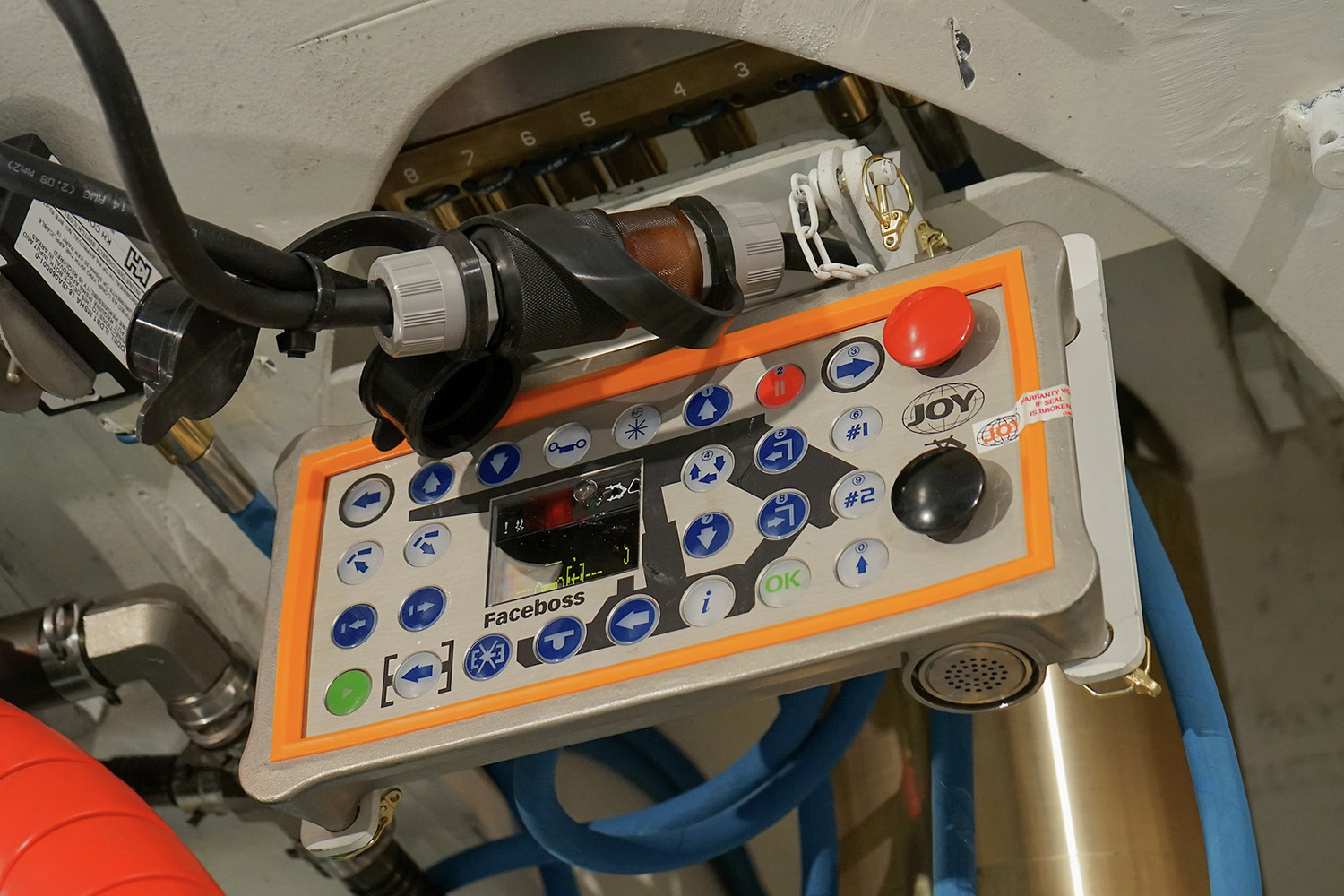

Highly efficient cycle times, consistency and reduced operator exposure to dust and noise. Fully programmed automated cutting sequences, including gate end turnarounds. Includes optimal drum positioning with automation software that positions the drum at a height that maintains a pre-configured pitch angle to the pans.