Underground hard rock bolters

ZB21

- Installable bolt lengths (ft) 5 - 8

- Installable bolt lengths (m) 1.5 - 2.4

- Maximum vertical reach (ft) 20 ft. 11 in

- Maximum vertical reach (m) 6 370

- Minimum bolting height (ft) 9 ft. 6 in

- Minimum bolting height (m) 2 893

Purchase options

Request a quoteExcellent versatility in a small-class bolting platform.

The innovative ZB21 offers convenience and productivity on a flexible common carrier platform. This solid workhorse allows completion of the bolting cycle from the operator enclosure to reduce human interaction with screens and bolts.

- 100% of bolting cycle can be performed from the operator’s compartment

- 2 of the major bolt types can be installed off a single carousel

- 100% tunnel bolting coverage — walls, and backs

Features and benefits

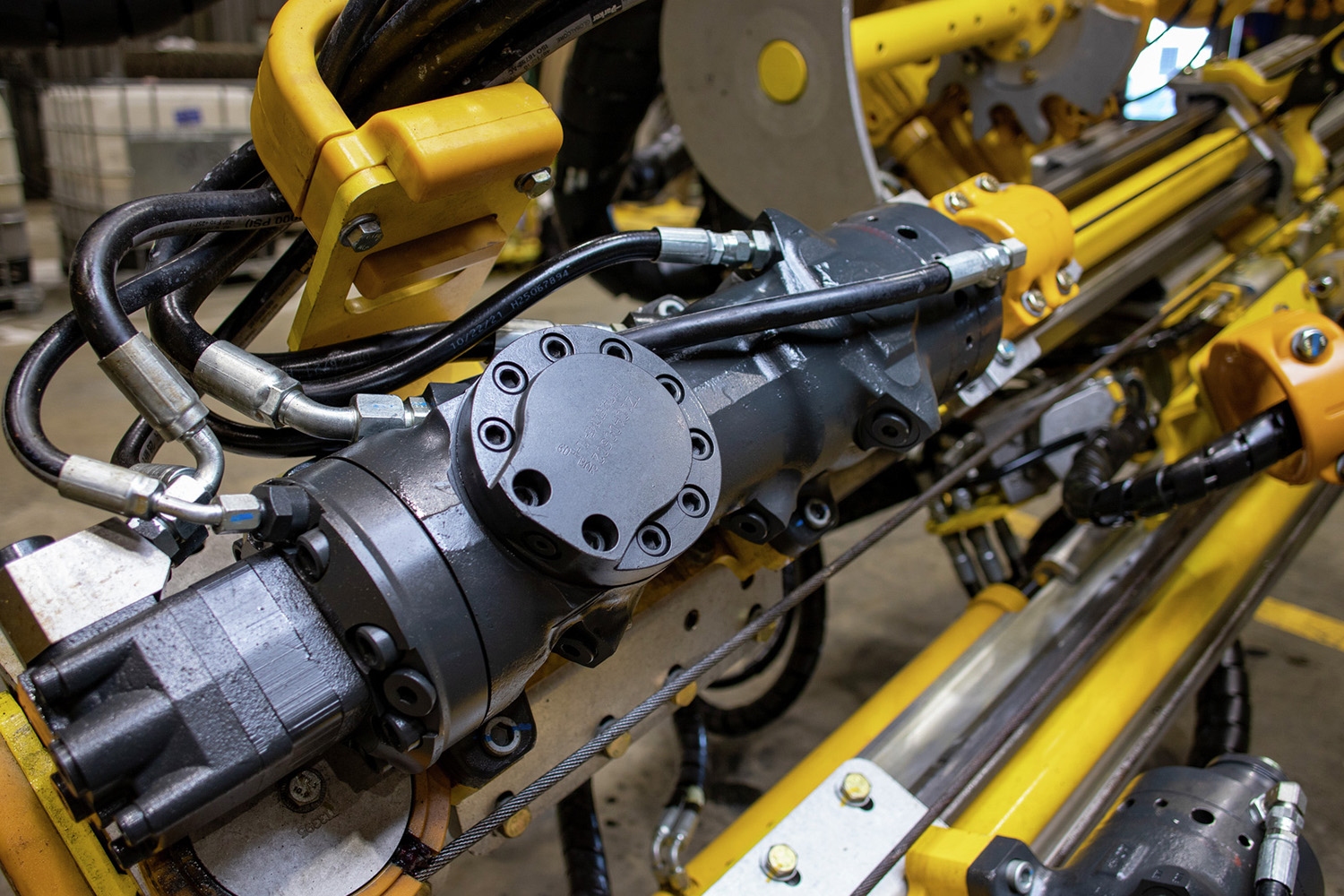

Innovative bolting head

Limited moving mechanical parts and a simple design for smooth operability. Reduced bolting cycle times and increased drifter uptime helps you keep production moving.

Performance-boosting operator enclosure

Ergonomic, ISO-compliant and ROPS/FOPS-certified cabins or canopies. Optional enclosed cabin available with climate control.

Productive drifters

Exceptional consumable life with technologies designed to enhance drilling productivity. Drifter model options include the Komatsu JZD08, JZD10 and JZD12, manufactured by Montabert.

Screen handler and chemical injection system

Integrated screen handling allows full completion of bolting cycle from inside the operator enclosure. New chemical injection system provides superior alignment and accuracy and can help boost productivity with reduced bolting cycle times.

Common carrier design between ZB21 and ZJ21

New platform offers universal controls, outer boom structure, driveline and operator enclosure configurations. Designed to give your mining operation versatility while simplifying maintenance and training.

Superior coverage

Exceptional coverage for vertical and horizontal reach. Ideal for fitting into many smaller mine sections and can use a variety of bolt types: mechanical, friction, chemical and hydro expanding.

Specifications

- Full specs

- Standard equipment

- Optional equipment

- Bolter hydraulics: Variable displacement piston pumps with load-sensing, for bolter head and boom movements.

- Controls: Intelsense control system incorporating these features: collaring, anti-jamming, auto return to start position following hole completion, and control levers for operating bolter head.

- Bolter position: Inline

- Boom quantity: 1

- Boom extension (mm): 1 200

- Boom extension (ft): 3 ft. 11 in

- Feed extension (ft): 1 ft. 5 in

- Feed extension (mm): 427

- Stinger extension (mm): 452

- Stinger extension (ft): 1 ft. 6 in

- Boom rollover: 360°

- Carousel capacity: 9 bolts

- Montabert drills: JZD08 (8 kW), JZD10 (10 kW), or JZD12 (12kW)

- Boom coverage height (ft): 22 ft. 3 in

- Boom coverage height (mm): 6 900

- Boom coverage width (ft): 25 ft. 2 in

- Boom coverage width (mm): 7 700

- Available bolt lengths (mm): 1 524, 1 829, 2 134 or 2 438

- Available bolt lengths (ft): 5, 6, 7 or 8

-

Leveling jacks

- Front (standard with unit): 2

- Rear (standard with unit): 2

-

Engine

- Bolters Model: Cummins QSB3.3

- Displacement (L): 3.3

- Certification: EPA Tier 3, MSHA

- Cooling Type: Water cooled, charge air cooled

- Air filtration: OHSA @ 100 cfm/hp = 9 900 cfm, MSHA-07-ENA110017 = 4 000 cfm

- Engine output (HP): 99 HP @ 2,600 rpm

- Engine output (kW): 74 kW @ 2 600 rpm

- Maximum torque (ft-lbs): 306 @ 1,600 rpm

- Maximum torque (N-m): 415 @ 1,600 rpm

-

Tires

- Tire type: Solid, lugged

- Size: 12.00 - 20

-

Axles

- Front and rear: Dana 112

- Differential: No-spin

- Service brake: Enclosed wet disc

- Parking brake: Hydraulically-released/spring-applied

- Oscillation angle (deg): +/- 7

-

Transmission

- Transmission: Dana T12000 series w/ integrated torque converter

- Shifting: Powershift

- Speeds: Two forward/two reverse

-

General

- Fuel tank capacity (L): 63

- Fuel tank capacity (US gal): 17

- Exhaust system: Diesel oxidation catalyst

- Exhaust system optional: Diesel particulate filter

- Alternator: 24V/60A

- Batteries: 2 x 12 V

- Starter: 24V heavy duty

- Tram lights: 2 front/2 rear

- Drill lights: 4 front

- General carrier hydraulics: Variable displacement piston pumps with load sense

- Oil tank volume (L): 180

- Oil tank volume (US gal): 48

- Steering hydraulics: Variable displacement piston pumps with load sense. Two double-acting steer cylinders.

- Tank filling: Mechanical pump

- Tank filling optional: Electric pump and/or wiggins

- Brake system: Totally enclosed service brake is hydraulically-applied, spring-released on front and rear axles with automatic brake application.

- ZJD08, ZJD10, ZJD12: One 56 kW (75 HP) TEFC electric motor (voltage as per application) NEMA 4 panels

- 1st gear (0% grade)(mph): 3.1

- 1st gear (0% grade)(km/h): 6.3

- 2nd gear (0% grade)(mph): 5

- 2nd gear (0% grade)(km/h): 10

- Cabin (optional): FOPS/ROPS Certified Enclosed Cabin - ISO 3449 (2005) and ISO 3471 (2008)

- Canopy: FOPS/ROPS certified - ISO 3449 (2005) and ISO 3471 (2008)

- Seat: Mechanical suspension seat

- Base unit (kg): 14 900

- Base unit (lbs): 33,220

- Fully optioned (kg): 17 100

- Fully optioned (lbs): 37,620

- LCD dash

- ROPS/FOPS certified canopy

- Mechanical suspension seat

- Joystick boom/drill controls

- LED working lights

- Parking brake

- Articulation lock brace mounted to machine

- 5 ft. bolter head

- Komatsu JZD08 drifters

- Fixed centralizers

- 5.5 kW air compressor

- Water pump

- Cable reel

- Mechanical fill for hydraulic tank

- Mechanical fire suppression

- Outriggers

- Intelsense

- Single 12 lb. fire extinguisher

- LCD dash

- ROPS/FOPS certified canopy

- Mechanical suspension seat

- Joystick boom/drill controls

- LED working lights

- Parking brake

- Articulation lock brace mounted to machine

- 5 ft. bolter head

- Komatsu JZD08 drifters

- Fixed centralizers

- 5.5 kW air compressor

- Water pump

- Cable reel

- Mechanical fill for hydraulic tank

- Mechanical fire suppression

- Outriggers

- Intelsense

- Single 12 lb. fire extinguisher

- Various voltages: 380V / 50Hz, 460V / 60Hz, 575V / 60Hz

- Cab (FOPS/ROPS certified) with air conditioning and/or heat

- Hydraulic centralizers

- Resin injection system

- Adjustable carousel for two bolt diameters

- Various bolt lengths can be handled with a single carousel

- Optional mesh handler

- Centralized greasing for boom

- 11 kW air compressor

- 85 m hose reel

- Pump

- High pressure water washer with 20 m reel

- Secondary 20 lb fire extinguisher

- Electric fill for hydraulic tank

- Beacon light kit

- Auto lubrication system

- Grease station with hose reel and drum pump

- Wheel chocks with bracket

- Specialized environment packages

Carrier options

- Rear view camera with screen

- Secondary fire extinguisher (20Lb)

- Electric fill for hydraulic tank

- Main filters have electric fault indicators

- Fast fill for hydraulic and fuel tanks (Wiggins fitting)

- Fittings for kidney loop filtration

- Audible backup alarm

- Fire detection and suppression system (check fire)

- Larger compressor to enable air mist drilling without mine air

- Water hose reel catering for 1 in water hose and 85 m

- Solid fill Tires

- 12VDC power supply in canopy

- 24VDC power supply in canopy

- 24VDC (switched) power supply in canopy

- 12VDC power port in canopy

- 2-way radio receptacle with antennae bracket (radio to be supplied by customer)

- Jump start receptacle

- Fully enclosed operators Cabin with air conditioning c/heater, filtered and pressurized, noise level in Cab with machine at full power less than 85dB(A)

- External park brake release system

- Beacon light kit

- Auto lubrication system (carrier only)

- High pressure water washer

- Centralized greasing for boom

- Optional grease station with hose reel and drum pump with drum stand

- 11 kW air compressor for air mist drilling/ air blast without mine air

- Pump

- Wheel chocks with bracket

Environment options

- High altitude package

- Artic package

- Harsh water package

- Various voltages: 380V / 50Hz, 460V / 60Hz, 575V / 60Hz

- Cab (FOPS/ROPS certified) with air conditioning and/or heat

- Hydraulic centralizers

- Resin injection system

- Adjustable carousel for two bolt diameters

- Various bolt lengths can be handled with a single carousel

- Optional mesh handler

- Centralized greasing for boom

- 11 kW air compressor

- 85 m hose reel

- Pump

- High pressure water washer with 20 m reel

- Secondary 20 lb fire extinguisher

- Electric fill for hydraulic tank

- Beacon light kit

- Auto lubrication system

- Grease station with hose reel and drum pump

- Wheel chocks with bracket

- Specialized environment packages

Carrier options

- Rear view camera with screen

- Secondary fire extinguisher (20Lb)

- Electric fill for hydraulic tank

- Main filters have electric fault indicators

- Fast fill for hydraulic and fuel tanks (Wiggins fitting)

- Fittings for kidney loop filtration

- Audible backup alarm

- Fire detection and suppression system (check fire)

- Larger compressor to enable air mist drilling without mine air

- Water hose reel catering for 1 in water hose and 85 m

- Solid fill Tires

- 12VDC power supply in canopy

- 24VDC power supply in canopy

- 24VDC (switched) power supply in canopy

- 12VDC power port in canopy

- 2-way radio receptacle with antennae bracket (radio to be supplied by customer)

- Jump start receptacle

- Fully enclosed operators Cabin with air conditioning c/heater, filtered and pressurized, noise level in Cab with machine at full power less than 85dB(A)

- External park brake release system

- Beacon light kit

- Auto lubrication system (carrier only)

- High pressure water washer

- Centralized greasing for boom

- Optional grease station with hose reel and drum pump with drum stand

- 11 kW air compressor for air mist drilling/ air blast without mine air

- Pump

- Wheel chocks with bracket

Environment options

- High altitude package

- Artic package

- Harsh water package

Videos

Feature segments: Komatsu hard rock drilling and bolting

The drilling and bolting process is one of mining’s biggest challenges. The new Komatsu ZB21 bolter has a lot of new innovations – including the ability to integrate the Jennmar J-LOK P pumpable resin injection system – to improve your operation.

Get a walkaround and benefits overview for our ZB21 bolter

Versatility and productivity in a small-class bolting platform.

A bolting cycle animation featuring the ZB21 bolter

The ZB21 has a common platform design with universal controls and and efficient drilling cycle with proven Montabert drifter technology.

Komatsu's integrated screen handling and bolting cycle bolts

For all your varying drill conditions, including multiple bolt type installations, we have everything you need to complete your bolting cycle at Komatsu.

Komatsu's Integrated screen handling and bolting cycle Chemical Bolts Installation

Get complete and safe mechanized ground support installation with no operator exposed or manual handling when using the integrated screen handler.

Interchangeability between bolt types means better compatibility

Komatsu features a full range of consumables for all installable bolt types, including dollies and drivers, centralizers, and carousel flowers.

- Video1

- Video2

- Video3

- Video4

- Video5

- Video6

360º view

Drag to rotate or click arrows

Find what works for you