Crushing

UFB-14S

Joy underground feeder breakers

- Seam height (cm) Greater than 190

- Seam height (in) Greater than 75

- Throughput (standard) (MTPH) Up to 1 360

- Throughput (standard) (TPH) Up to 1,500

- Breaker pick force (kg) Up to 40 823

- Breaker pick force (lbs) Up to 90,000

Integral to your operation’s productivity

Developed to provide the same traditional reliability and low cost of ownership as previous designs, the UFB-14S reduces manufacturing lead times, drives improved inventory and is more maintenance-friendly.

- Lower total cost of ownership than a custom solution

- More maintenance friendly; improved parts availability*

- Reduced manufacturing lead time*

Note: *compared to a custom Komatsu solution

Resources

Features and benefits

Promotes increased productivity

Since the feeder breaker is located closer to the working face, haulage distances and travel times are reduced, resulting in increased production and efficiency of the remaining section equipment.

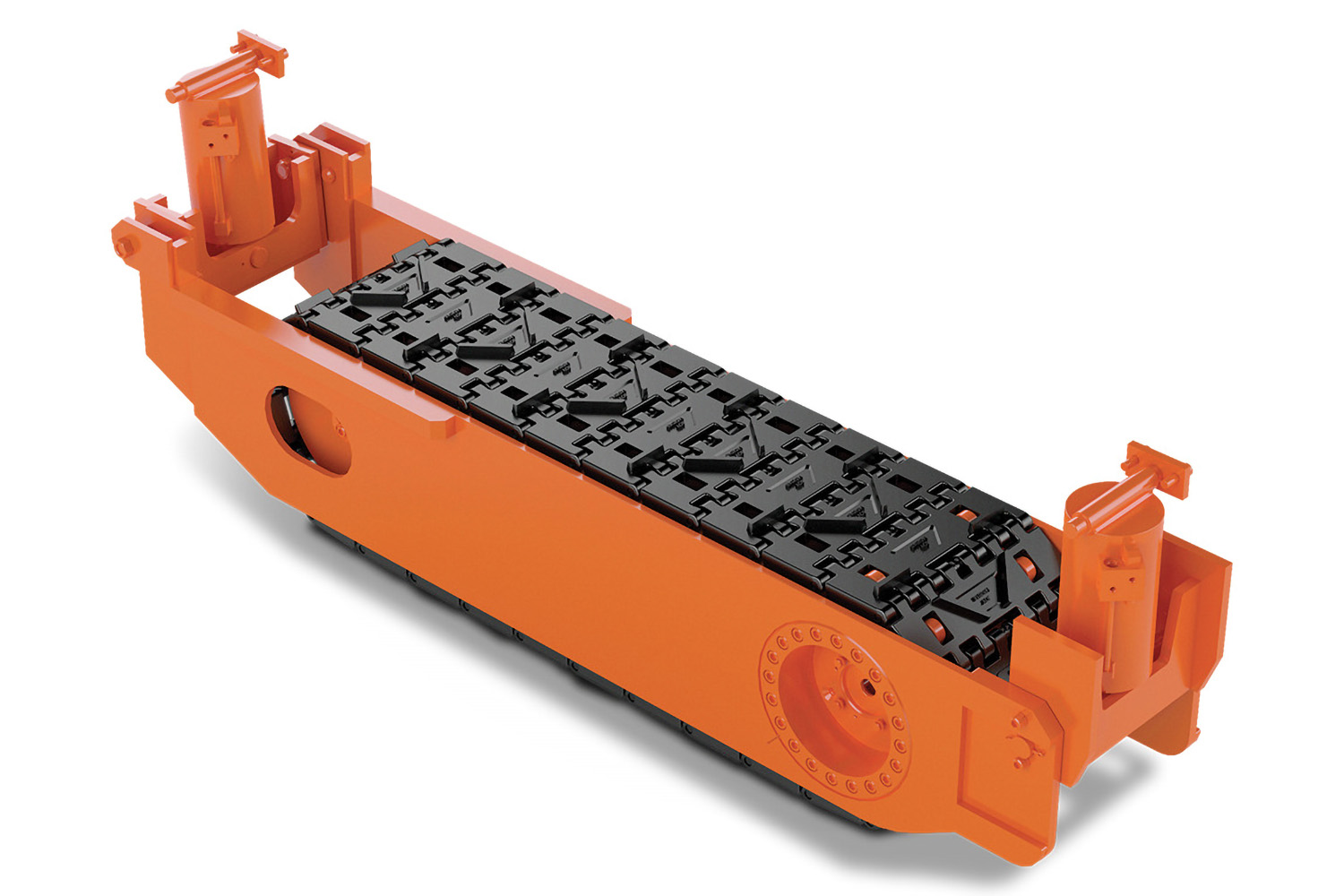

Easier section moves

Engineered to handle abrasive material conditions, the robust crawler drive and undercarriage are also designed to offer exceptional ground clearance and towing capabilities.

![Optidrive VFD [option]](/content/dam/komatsu/photos-images/kx-jpegs/1114098_GPL2112_withGPL6391VFD_forcrushingwebsite-image-1280x1280.jpeg)

Optidrive VFD [option]

Joy Optidrive, an AC variable-frequency drive system, integrates software with the electronic and mechanical systems to provide precise conveyor speed control and breaker overload protection.

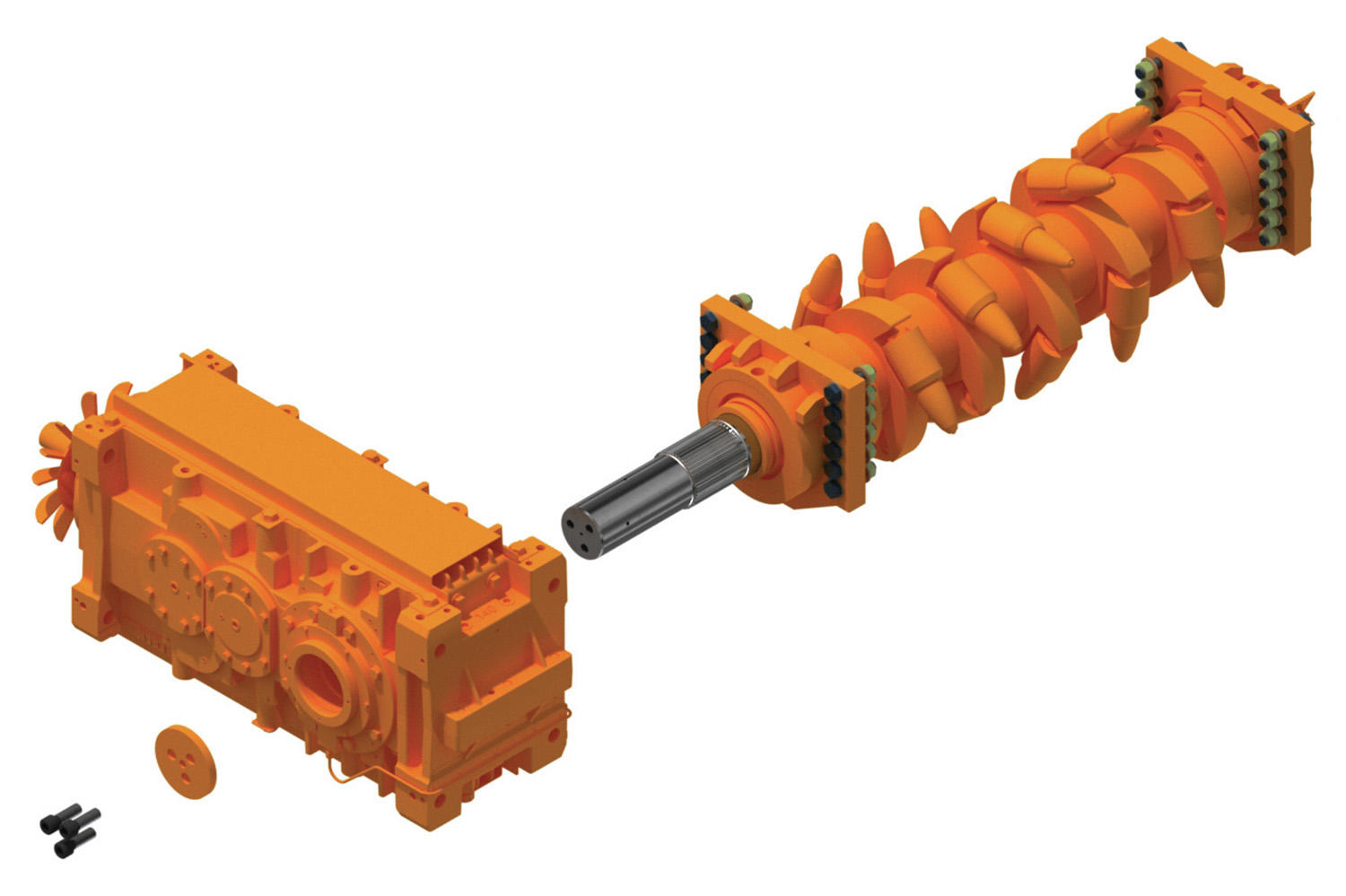

Splined breaker shafts

Splined connection versus a compression connection can reduce assembly and disassembly time by more than 50%, reducing downtime for replacement and service. Splined connection is also 25% stronger than previous connections.* *based on internal testing

![Bolt-on flights [option]](/content/dam/komatsu/websites/en-us/equipment-product/marketing/crushing/joy-underground-feeder-breakers/839955_under-ground-ufb-literature-link-bolt-on-flights-web.jpg)

Bolt-on flights [option]

Downtime to replace conveyor flights is reduced by up to 75% with an easy bolt-on, alloy steel flight design. Operators have the flexibility to add additional flights and improve product sizing.

Camera system

Forward and rearward cameras provide remote monitoring of haulage equipment receiving payload and discharging onto the material handling system.