Crushing

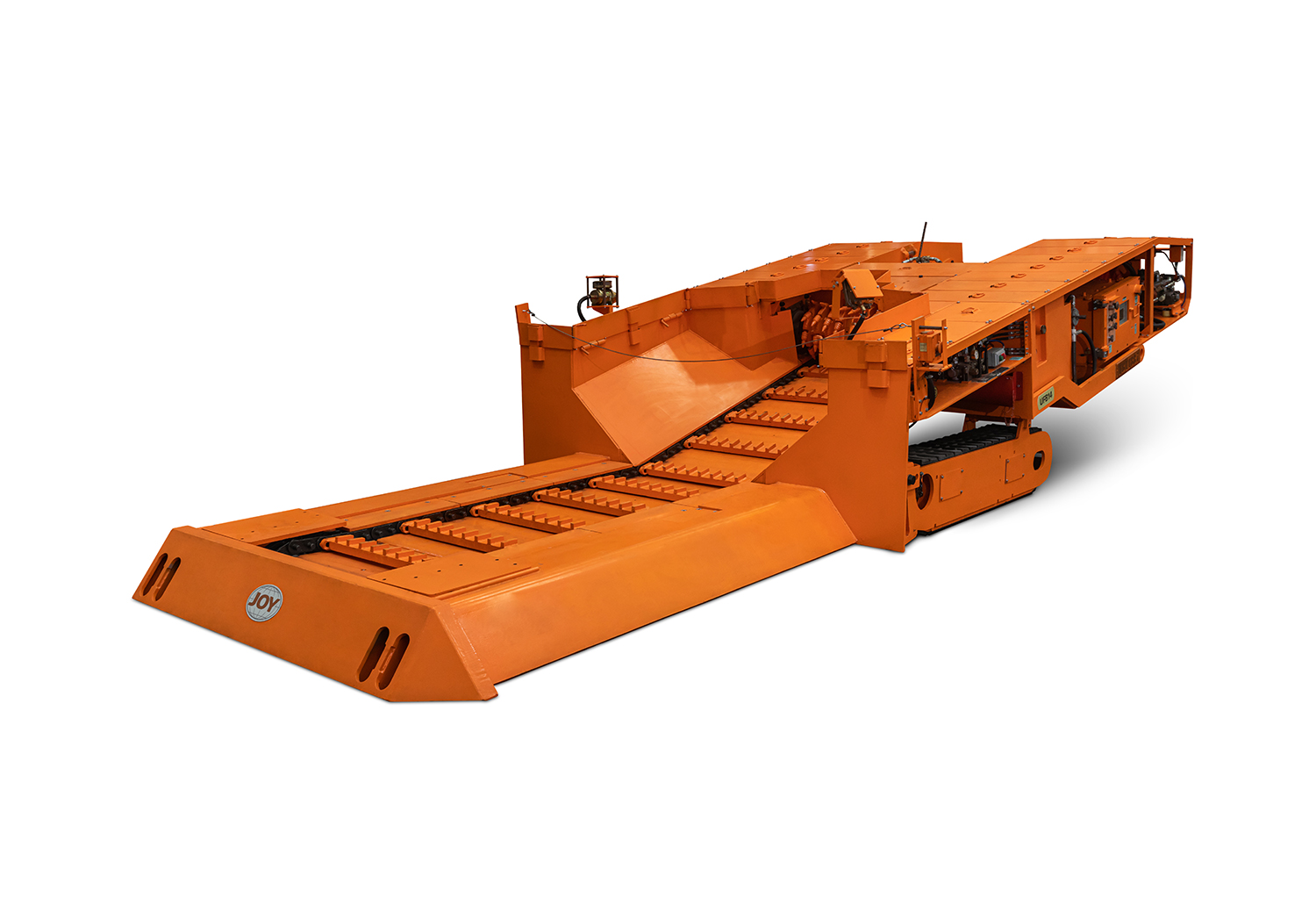

UFB-14LS

Joy underground feeder breakers

- Seam height (cm) Greater than 150 cm

- Seam height (in) Greater than 59 in

- Throughput (standard) (TPH) Up to 881 TPH

- Throughput (standard)(MTPH) Up to 800 MTPH

- Breaker pick force (kg) Up to 36 823 kg

- Breaker pick force (lbs) Up to 81,180 lbs.

Integral to your operation’s productivity

The Joy UFB-14LS feeder breaker is designed to cut operating costs and increase production rates by helping your mining, haulage and conveying systems to work efficiently. This machine provides a reliable means for continuous feeding and breaking of most bedded, mined materials.

- High throughput feeder breaker

- Flexible for various machine options

- Quick belt moves with attached tailpiece

Resources

Features and benefits

Promotes increased productivity

Since the feeder breaker is located closer to the working face, haulage distances and travel times are reduced, resulting in increased production and efficiency of the remaining section equipment.

Easier section moves

Equipped with a powerful crawler drive system for quick, efficient belt moves. Plus, the feeder breaker can be connected to the conveyor belt to move them both simultaneously, saving time.

![Optidrive VFD [option]](/content/dam/komatsu/photos-images/kx-jpegs/1114098_GPL2112_withGPL6391VFD_forcrushingwebsite-image-1280x1280.jpeg)

Optidrive VFD [option]

Joy Optidrive, an AC variable-frequency drive system, integrates software with the electronic and mechanical systems to provide precise conveyor speed control and breaker overload protection.

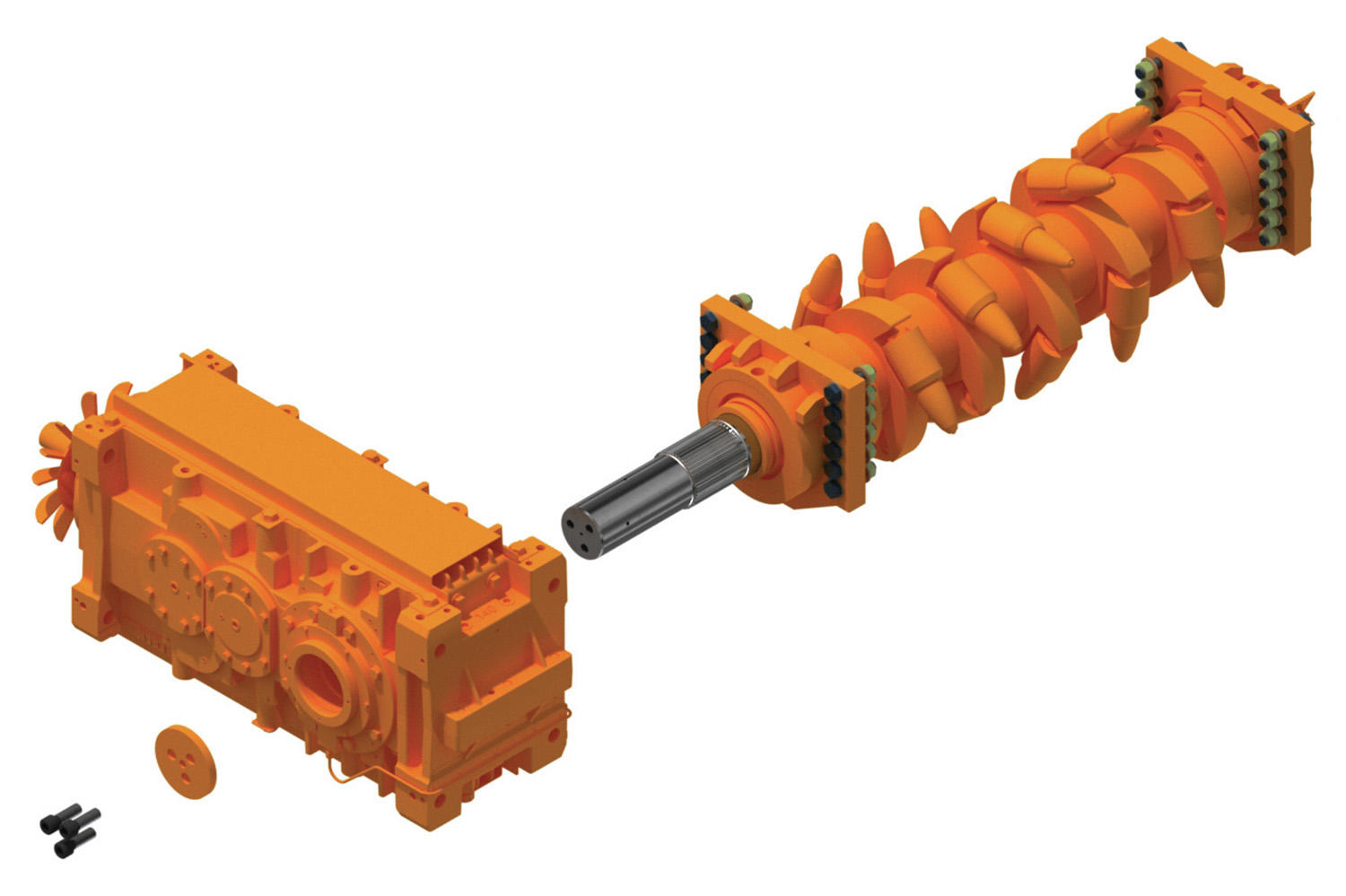

Splined breaker shafts

Splined connection versus a compression connection can reduce assembly and disassembly time by more than 50%, reducing downtime for replacement and service. Splined connection is also 25% stronger than previous connections.* *based on internal testing

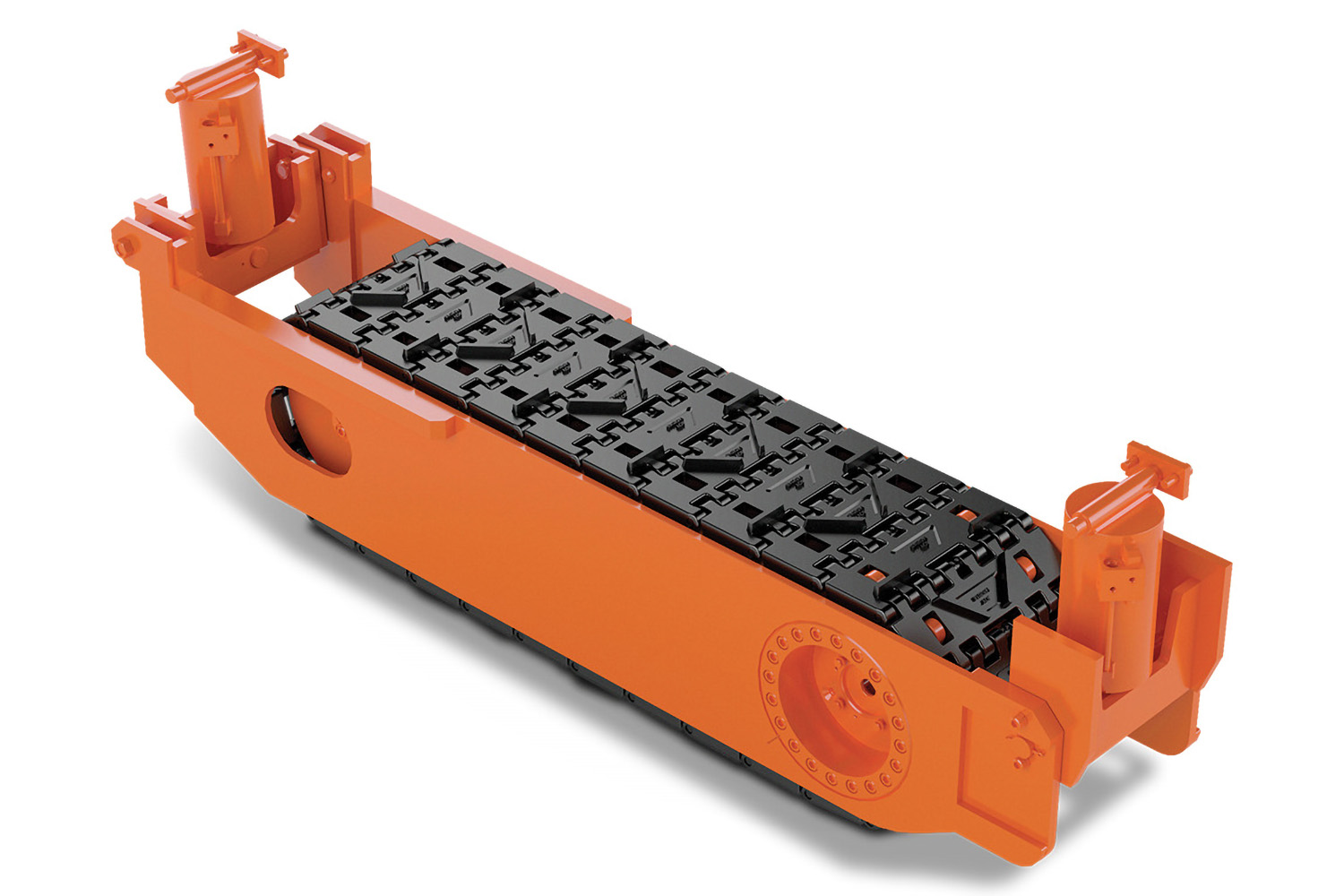

![Bolt-on flights [option]](/content/dam/komatsu/websites/en-us/equipment-product/marketing/crushing/joy-underground-feeder-breakers/839955_under-ground-ufb-literature-link-bolt-on-flights-web.jpg)

Bolt-on flights [option]

Downtime to replace conveyor flights is reduced by up to 75% with an easy bolt-on, alloy steel flight design. Operators have the flexibility to add additional flights and improve product sizing.

Camera system

Forward and rearward cameras provide remote monitoring of haulage equipment receiving payload and discharging onto the material handling system.

Specifications

- Full specs

- Breaker pick force (lbs): Up to 81,180 lbs.

- Breaker pick force (kg): Up to 36 823 kg