Faceboss Control System

Help optimize your operation with actionable insights. Operator assistance tools, automated sequences, advanced diagnostics and machine performance monitoring from the Faceboss Control System.

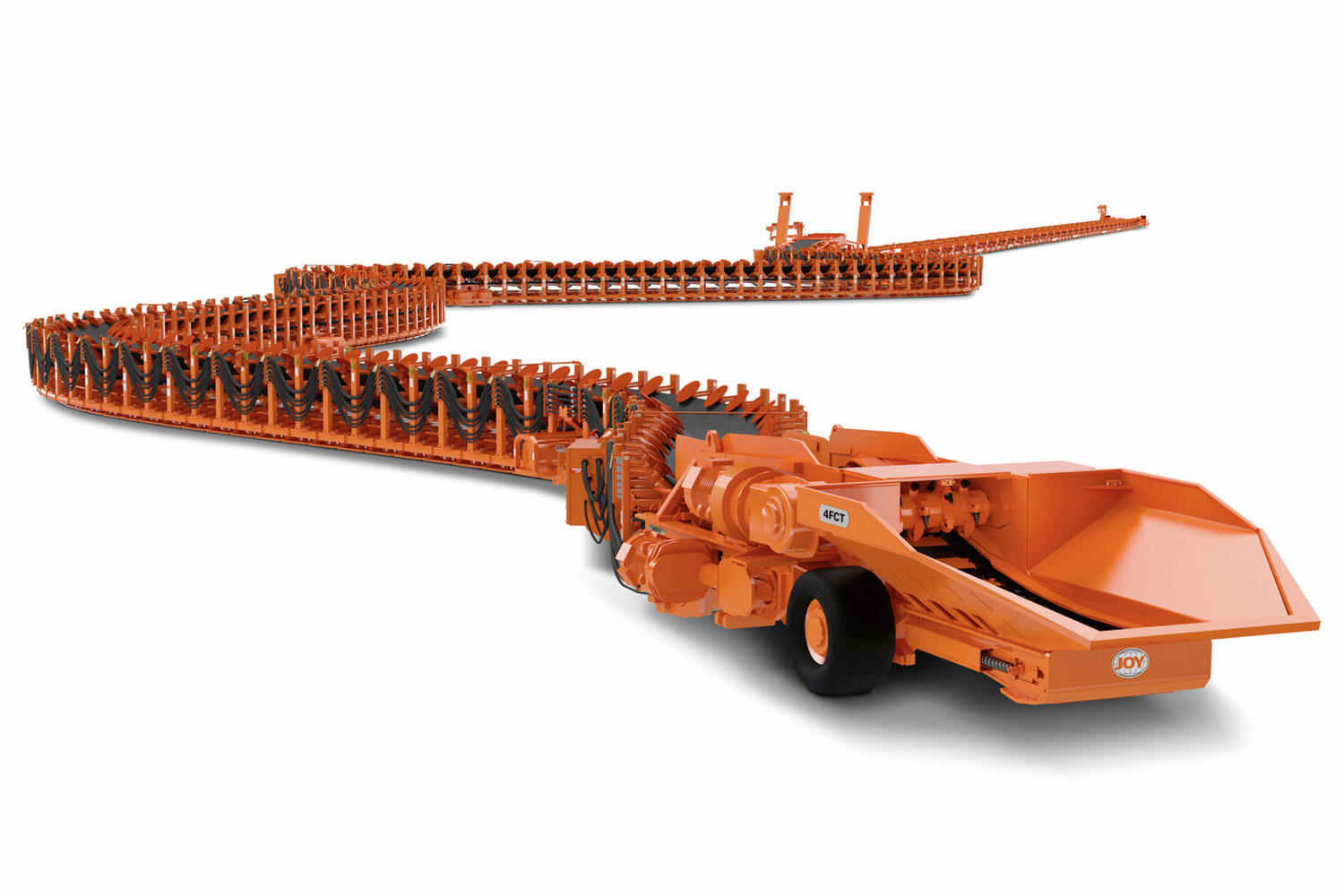

Truly continuous haulage for your room and pillar, longwall and industrial mineral operations is now within reach. The 4FCT can transform your transport by reducing or even eliminating haulage-related bottlenecks, so your continuous miners can operate at maximum capacity.

Remove the need for a feeder breaker in the section with an integrated lump breaker that helps size the product, meter the flow onto the belt, and eliminate a transfer point.

When hauling with vehicles, gaps and bottlenecks inevitably happen. But with the 4FCT, you keep material moving constantly. And the 4FCT can convey and tram simultaneously, following a continuous miner’s every move.

Each 4FCT system includes a Dynamic Move-Up Unit (DMU) that interfaces with your mine's panel belt. Available in two styles: side-discharge, best in low seam heights/wide entries and over-the-top, best in higher seams with restricted width.

The 4FCT’s Optidrive power system provides variable control of traction, belt and chain conveyor motors. Your crews can maximize belt loading and minimize belt speed, thus extending belt wear life and minimizing spillage.

With the Faceboss control system, your operators can manage equipment at an optimal balance of production rate and cost-per-ton. They have access to automated sequences, advanced diagnostics, machine performance monitoring and analysis tools.

Keep personnel and machines in a section to minimum, as the 4FCT requires only one operator using remote control. Fewer people and machines means fewer visibility concerns in a confined area versus batch haulage. Better dust control, too.

Help optimize your operation with actionable insights. Operator assistance tools, automated sequences, advanced diagnostics and machine performance monitoring from the Faceboss Control System.

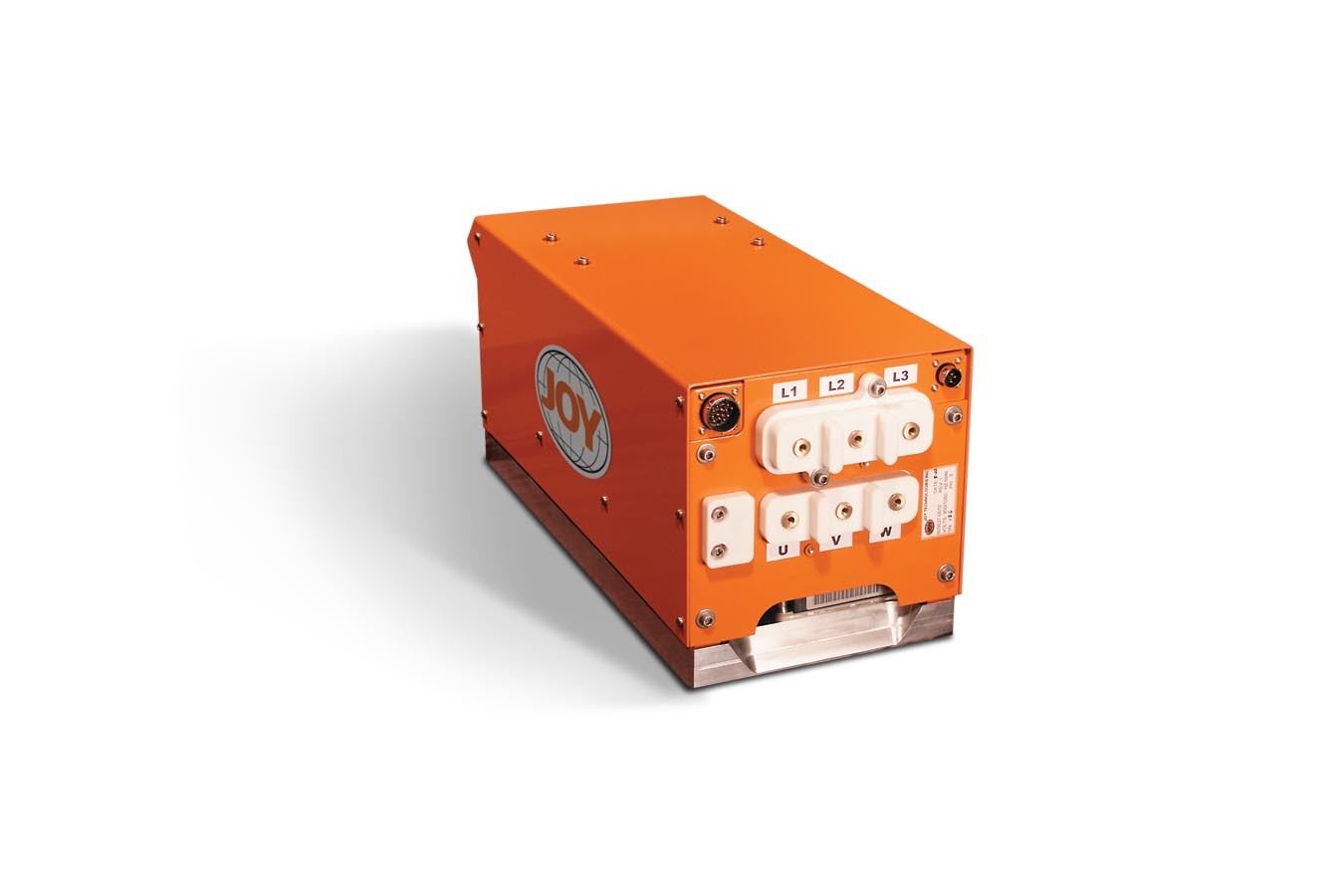

The Optidrive variable frequency drive system is the result of a holistic approach to transmission design that provides you with an adaptable, rugged and reliable solution for shearer traction systems. The medium voltage (MV, 3300 or 4160 V) OptiDrive system integrates the variable speed drive with the motor to achieve outstanding speed and torque control for soft starts and stops and fast acceleration. The variable chain speeds allow your operators to adapt to production conditions, giving you an opportunity to increase capacity, improve cutting cycles, and achieve remarkable efficiency with your longwall system.

With the FCT in follow me mode, the machine uses sensor technology to position itself under the miner tail while in production. Whether the miner is advancing into the cut, or tramming backwards, the FCT will adjust appropriately freeing the FCT operator to do more critical tasks. Since the FCT and miner are now communicating with each other, the FCT can match the miner tram speed exactly allowing for more precise movements resulting in a smoother interaction between equipment and extending machine life.