Longwall

Longwall automation

Progress in mining over the centuries has been primarily driven by advances in the design of tools and machines. The next generation of mining will be driven by advances in data and technology.

That’s where Komatsu’s Smart Mining comes in.

It’s a combination of advanced machine sensors and control systems, automation technology and powerful data analysis. It can help you mine more safely by removing workers from the operation. Mine more productively for increased profitability. And mine more sustainably.

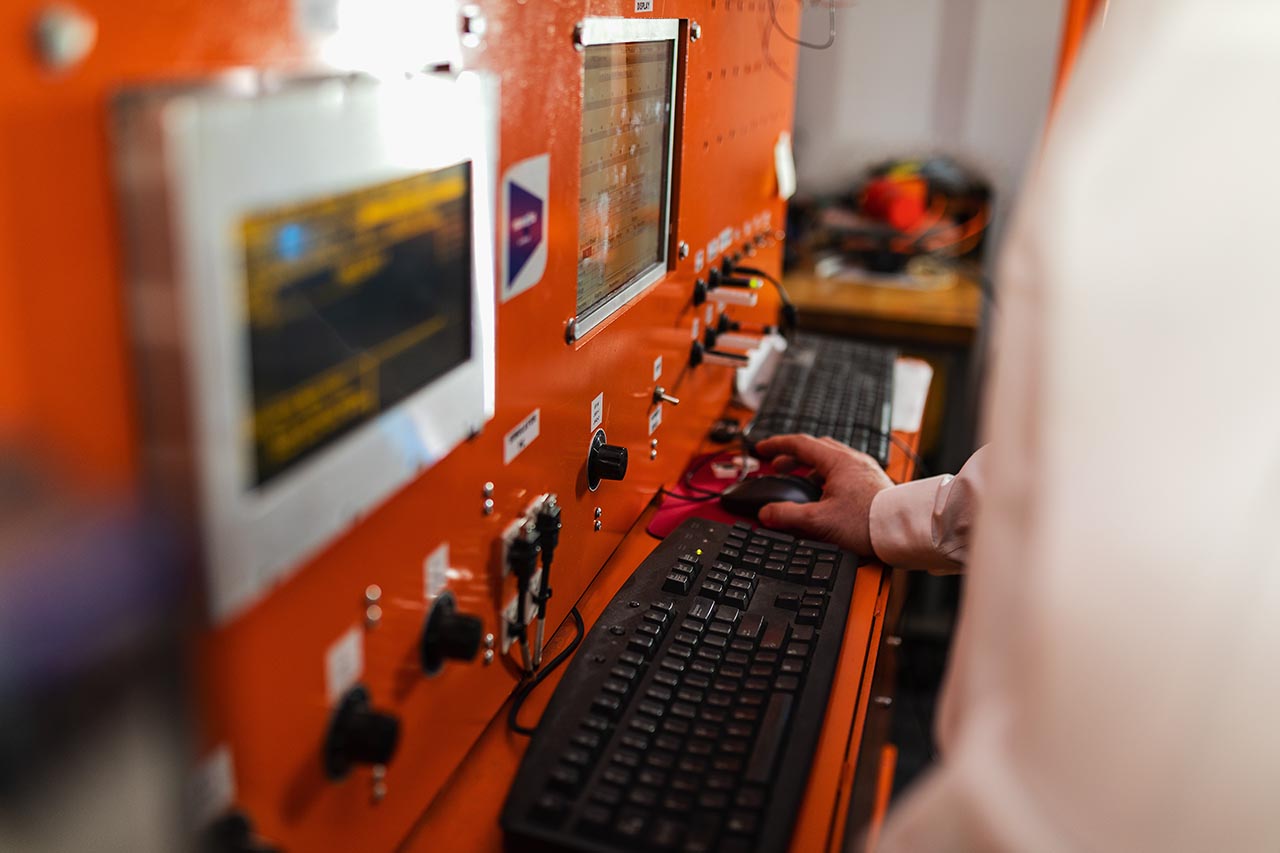

Remote operations a “significant step change”

With the operating height narrowing substantially on the southern end of the mine, Centennial needed a remote solution to keep operators from harm and production going strong. Komatsu provided cutting-edge and customized software so that operators could become proficient at remote operations and meet the imminent challenges of the “pointy end.”

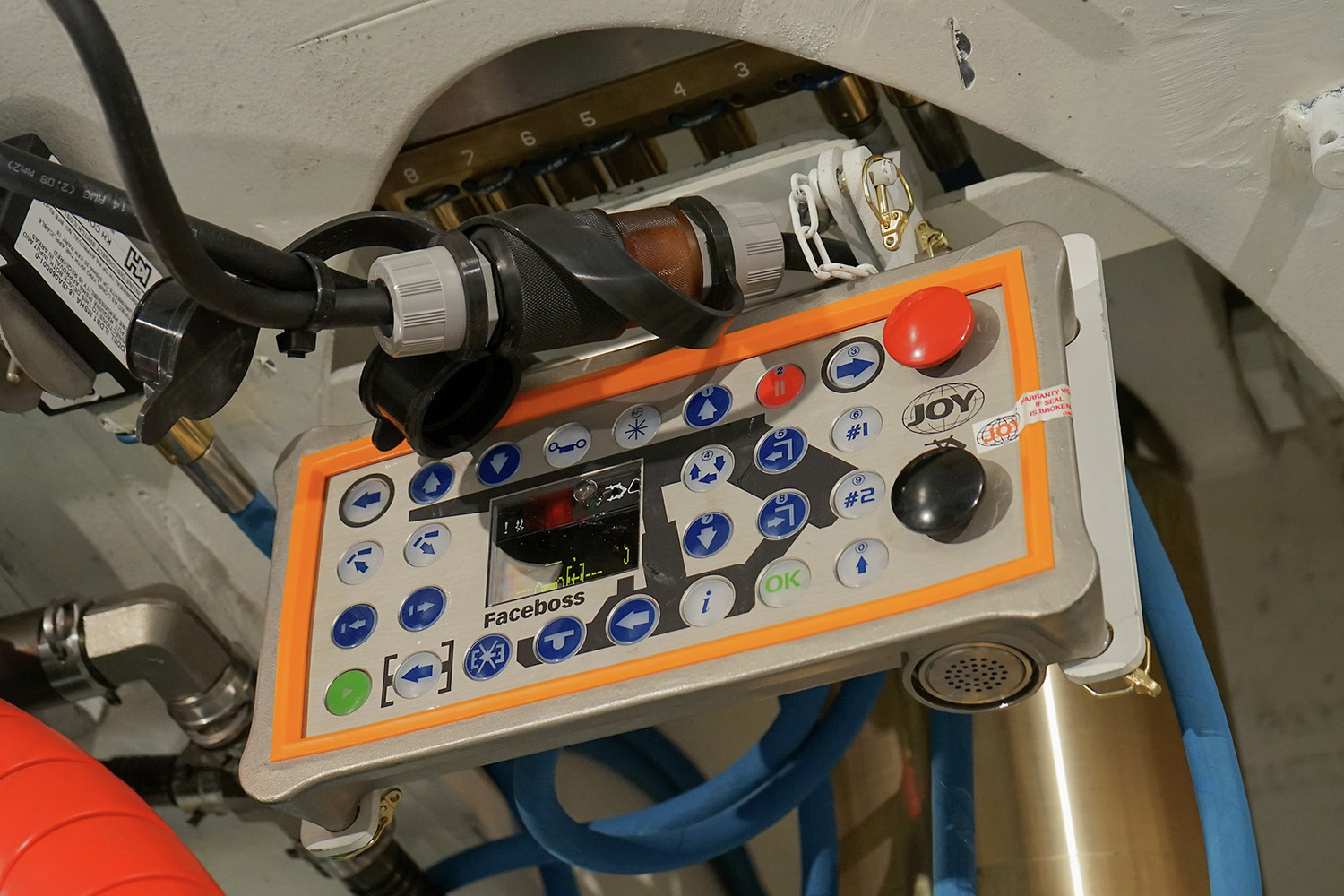

RS20n trailer

The Joy Faceboss RS20n longwall control system makes that possible by helping you unlock the benefits of automation and intelligent controls. It enables the connection of intelligent devices, sensors and technologies to the mine’s network to support high levels of longwall automation. Designed for use on PRS and AFCs, the Joy Faceboss RS20n is the industry’s first 1Gb/s two-wire Ethernet system, engineered for standout productivity and reliability. It enables high-speed video and data transfer, a full suite of advanced automation controls and exceptional remote management capabilities — all without the need for additional cabling or infrastructure.