Electric rope shovels

4800XPC

- Nominal payload (metric tons) 123

- Nominal payload (short tons) 135

- Dipper capacity (m^3) 66 - 70

- Dipper capacity (yd^3) 86 - 92

- Production (MTPH) 8 810 - 11 748

- Production (TPH) 9,712 - 12,950

Inspired design. Powerful cutting force.

Built for tough environments, the 4800XPC ultra-class three-pass-loading-tool delivers consistent uptime and high cutting force. Engineered for increased digging power and faster cycle times, utilizing the latest mining technology.

- Double-sided loading of manned and autonomous fleets

- Three-pass loading

- Low cost per tonne loading

Resources

Features and benefits

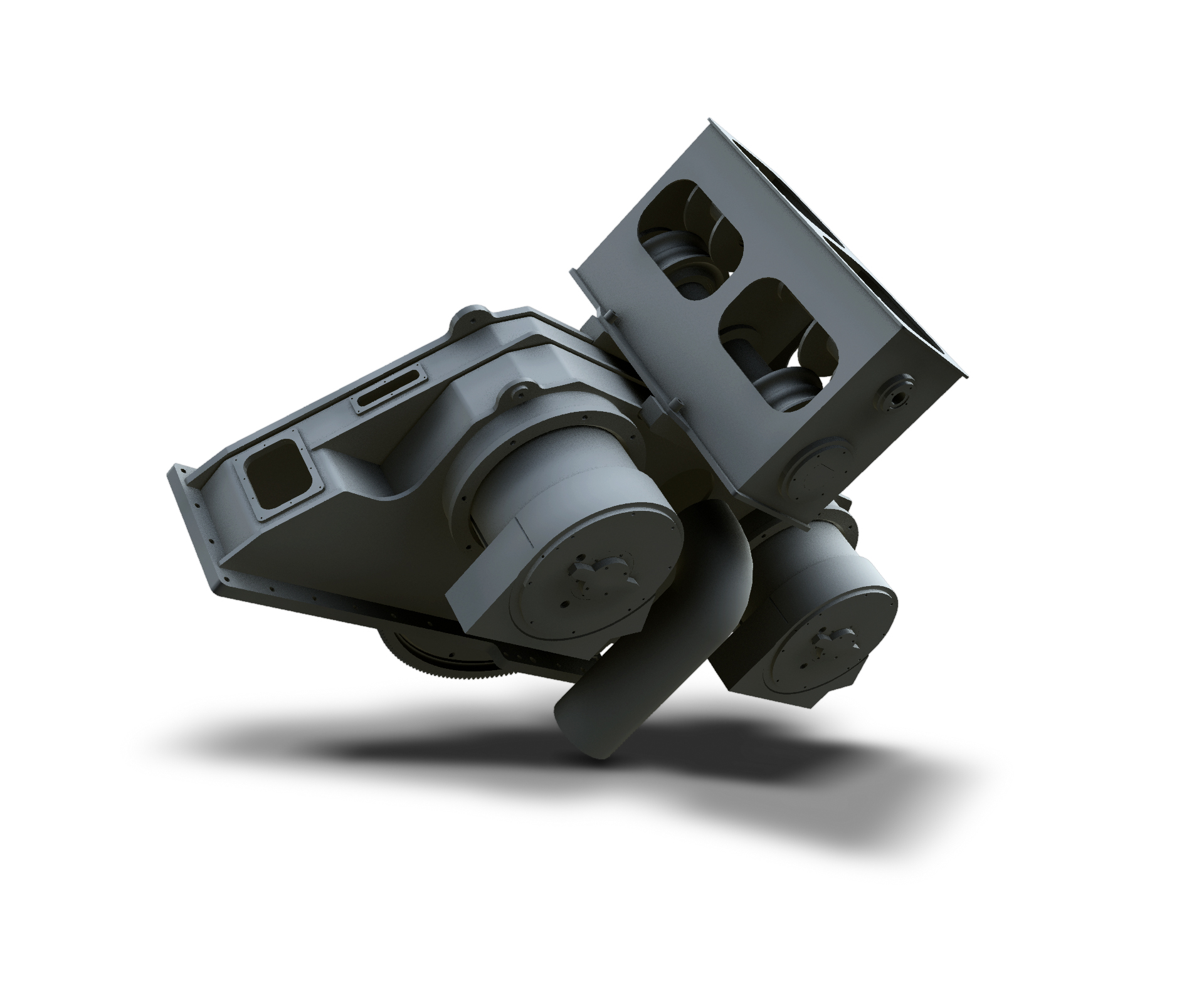

Direct Drive Crowd

The low inertia design of the responsive, dynamic crowd design system allows fine motion control by shovel operators, high crowd forces to assist with toe penetration, and reduced damage associated with abuse events.

Stability throughout the dig cycle

Built to handle hard materials with focus on penetrating the bank, the P&H twin leg handle focuses energy and cutting force by preventing the twisting or rotating of the dipper.

Latest dipper technology

The dipper is one of the hardest working pieces on your shovel. The 4100/4800 features the latest in dipper technology: a low-maintenance latching system, optimal toe penetration and the ability to pass match shovels with trucks.

Controls designed to boost production

P&H Adaptive Controls is a suite of integrated control functions designed to build on the strengths of the P&H shovel. Engineered to increase production by up to 9% and eliminate boom jacking by up to 50% with no negative effects on shovel structures.

Protects tracks and undercarriage

The P&H Track Shield helps protect your machine’s tracks and undercarriage from dipper strikes. It monitors dipper movement and position to help you predict imminent collisions and takes appropriate actions to mitigate damage to dipper or tracks.

Delta style undercarriage

Minimize maintenance with a proven shoe and tumbler that requires minimal intervention and allows for operation in a loose track configuration.

Specifications

- Full specs

- Nominal dipper capacity* (yd^3): 86 - 92 (SAE struck)

- Nominal dipper capacity* (m^3): 65.7 - 70.3 (SAE struck)

- Rated suspended load (st): 246.5

- Rated suspended load (mt): 224

- Optimum truck size (360 mt (400 st) truck shown) (st): 400

- Optimum truck size (360 mt (400 st) truck shown) (mt): 360

- Nominal payload dipper capacity note: *Payload and dipper capacity are dependent on many factors. Contact Komatsu Mining for an analysis of your specific application.

- Height of cut (ft): 62 ft. 2 in

- Height of cut (m): 18.9

- Radius of cut (ft): 78 ft. 7 in

- Radius of cut (m): 24

- Dumping height* door open (ft): 35 ft. 7 in

- Dumping height* door open (m): 10.8

- Maximum dump reach (furthest distance to center of truck) (m): 19.4

- Maximum dump reach (furthest distance to center of truck) (ft): 63 ft. 6 in

- Floor level radius (m): 16.2

- Floor level radius (ft): 53 ft. 3 in

- Tail swing radius (m): 9.9

- Tail swing radius (ft): 32 ft. 7 in

- Operator eye level (m): 10.1

- Operator eye level (ft): 33 ft. 1 in

- Crowd: Twin low inertia AC motors minimize shock loading and boom jacking. Direct drive crowd eliminates belt maintenance for improved responsiveness. Modular crowd motors with integral pinions provide for simplified motor replacement. Two input pinions share load for extended life. Dual spring-set air release brakes for reliable redundant operation.

- Swing: Three modular P&H planetary gear cases of proven design and a single piece forged swing gear transmit torque for fast cycle times. Spring-set air release disc brakes – one per motor. Splash lube filtration system.

- Adaptive controls technology: Smart control and application of power to improve payload and digging performance of machine. Increases shovel digging power without sacrificing life. Reduces loading from non productive impacts. Decreases operator fatigue by limiting rocking motions of the shovel especially in difficult digging conditions.

- Supply voltage: 7,200 or 13,800 V 3 Phase, 60 Hz or 6,000, 6,600, 7,200 or 11,000 Hz, 3 Phase, 50 Hz

- Supply transformer: Minimum 3,750 kVA

- Minimum short circuit VA available at shovel: 30 MVA

- Supply voltage note: *Voltage per customer requirements

- Propel: Propel on demand provides rapid transfer to propel mode. Rapid transfers allow frequent positioning of the shovel to the bank resulting in faster cycle times and more efficient digging. Two rugged P&H planetary gear cases of proven design independently transmit torque to the drive sprockets, producing the tractive effort required for fast, efficient propel and positioning operations. P&H brand Delta drive low tension sprocket drive system with heavy duty cast crawler shoes. Spring-set air release disc brakes – one per motor.

- Hoist time (s): All gearing housed in single enclosed gear case with filtered oil circulation for reliable splash lubrication and ease of maintenance. Large 68 in diameter hoist drum for extended rope bending life. Ferrule becket system and dual electric tuggers are standard for efficient rope change. Spring-set air release disc brakes – one per motor. Hoist rope fleeting sheave protects rope from excessive oscillation.

Videos

Teck Fording River achieves productivity and availability gains with the 4800XPC

At Teck Fording River, one of Canada’s leading mining companies, the P&H 4800XPC electric rope shovel is helping the site reach its coking coal production goals — day in, day out.

A review of the 4800 electric rope shovel technology

The P&H shovel family brings to bear more than 100 years of expertise in designing and engineering tough, smart loading machines built to pursue the lowest cost/ton operation in the industry.

Product spotlight: P&H 4800XPC Electric Rope Shovel

Built for tough environments, the 4800XPC ultra-class three-pass-loading-tool delivers consistent uptime and high cutting force. Engineered for increased digging power and faster cycle times, utilizing the latest mining technology.

- c1

- c2

- c3