Crushing

UFB-14S

Joy underground feeder breakers

- Seam height (cm) Greater than 190

- Seam height (in) Greater than 75

- Throughput (standard) (TPH) Up to 1,500

- Throughput (standard)(MTPH) Up to 1 360

- Breaker pick force (kg) Up to 40 823

- Breaker pick force (lbs) Up to 90,000

Integral to your operation’s productivity

Developed to provide the same traditional reliability and low cost of ownership as previous designs, the UFB-14S reduces manufacturing lead times, drives improved inventory and is more maintenance-friendly.

- Lower total cost of ownership than a custom solution

- More maintenance friendly; improved parts availability*

- Reduced manufacturing lead time*

Note: *compared to a custom Komatsu solution

Resources

Features and benefits

Promotes increased productivity

Since the feeder breaker is located closer to the working face, haulage distances and travel times are reduced, resulting in increased production and efficiency of the remaining section equipment.

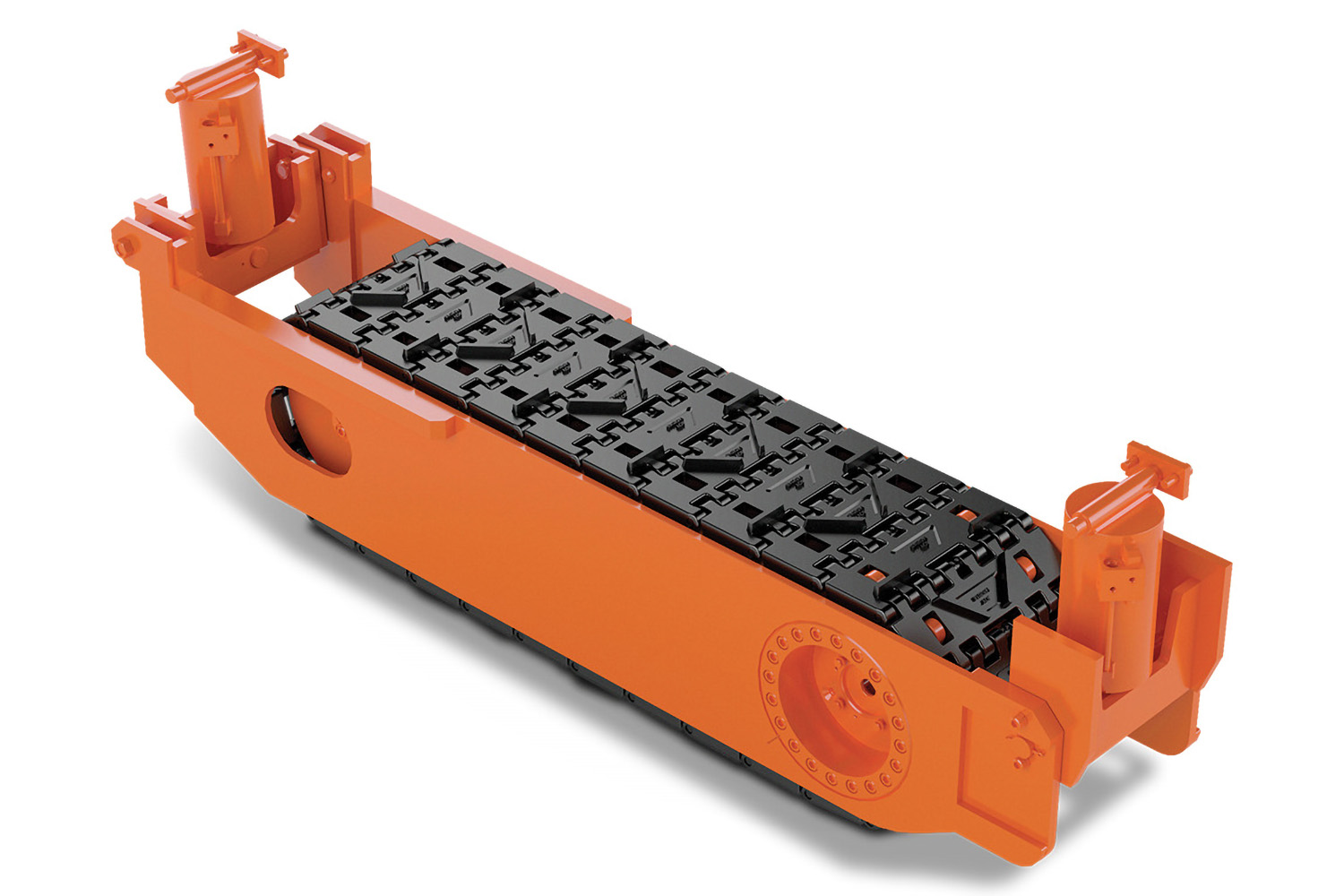

Easier section moves

Engineered to handle abrasive material conditions, the robust crawler drive and undercarriage are also designed to offer exceptional ground clearance and towing capabilities.

![Optidrive VFD [option]](/content/dam/komatsu/photos-images/kx-jpegs/1114098_GPL2112_withGPL6391VFD_forcrushingwebsite-image-1280x1280.jpeg)

Optidrive VFD [option]

Joy Optidrive, an AC variable-frequency drive system, integrates software with the electronic and mechanical systems to provide precise conveyor speed control and breaker overload protection.

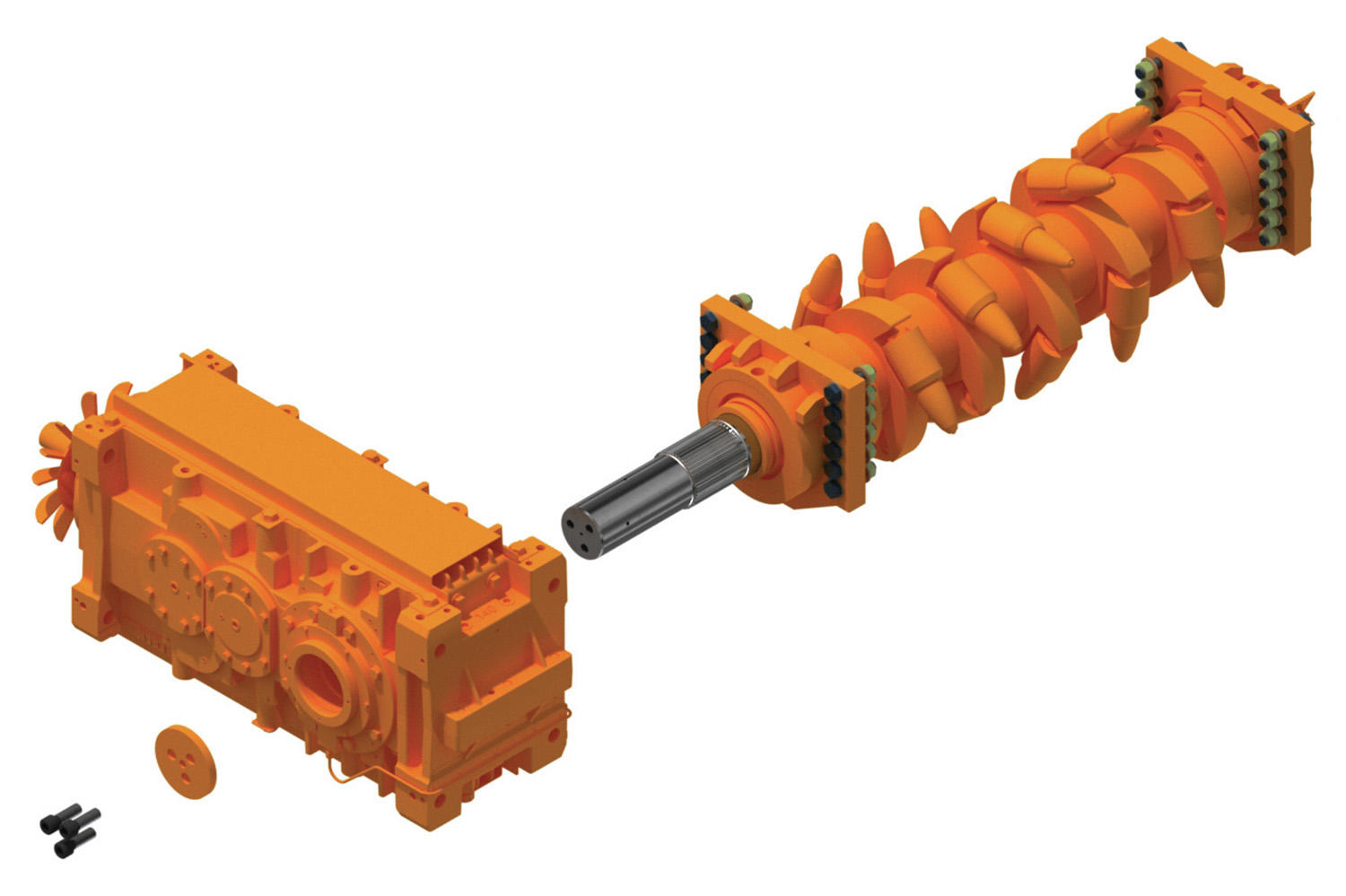

Splined breaker shafts

Splined connection versus a compression connection can reduce assembly and disassembly time by more than 50%, reducing downtime for replacement and service. Splined connection is also 25% stronger than previous connections.* *based on internal testing

![Bolt-on flights [option]](/content/dam/komatsu/websites/en-us/equipment-product/marketing/crushing/joy-underground-feeder-breakers/839955_under-ground-ufb-literature-link-bolt-on-flights-web.jpg)

Bolt-on flights [option]

Downtime to replace conveyor flights is reduced by up to 75% with an easy bolt-on, alloy steel flight design. Operators have the flexibility to add additional flights and improve product sizing.

Camera system

Forward and rearward cameras provide remote monitoring of haulage equipment receiving payload and discharging onto the material handling system.

Specifications

- Full specs

- Electrical Compliance: Dust-Tight/ Non-Permissible

-

General

- Machine voltage: 1,000 VAC @ 60 Hz

- Control voltage: 120VAC @ 60 Hz

- Control voltage type: 120 VAC @ 60 Hz

- Recommended size: 2/0 FOR 1000V SHD-GC

- Trailing cable: Supplied by customer

- Trailing cable recommended size: Recommended Size: 2/0 FOR 1000V SHD-GC, supplied by customer

-

Electric controller

- PLC - logic electric system: PLC - logic electric system: MicroLogix 1400 PLC with diagnostic display

-

Electric motors

- Conveyor drive (HP): 200

- (1) Breaker / conveyor drive (kW): 150

- (1) Breaker / conveyor drive (HP): 200

- (1) Breaker / conveyor drive voltage: 1,000 VAC @ 60 Hz

- (1) Conveyor reversing / jogging drive (HP): 5

- (1) Conveyor reversing / jogging drive (kW): 3.7

- (1) Conveyor reversing / jogging drive voltage: 1,000 VAC @ 60 Hz

- (2) Conveyor reversing / jogging drive voltage: Interlocked to prevent operation when main drive active.

- Conveyor reversing / jogging drive: 5 HP (3.7 kW)

- Conveyor reversing / jogging drive voltage: 1,000 VAC @ 60 Hz

- Interlocked: To prevent operation when main drive active.

-

Electrical operation

- Conveyor start method: 3 photo eyes

- Start-up warning horn: 20-second delay for start

- Electrical operation: High oil temperature switch, vacuum switch, breaker speed switch.

- E-stops: Push button and one oen each side of machine

- Panic bar located at tram controls: 305 mm (12 in) tape switch

- Tram enable: Push button

- Electric breaker (kW): 150

- Electric controller: PLC - logic electric system and microLogix 1400 PLC with diagnostic display

- Electric motor voltage: 1,000 VAC @ 60 Hz

- Machine voltage specifics: 1,000 VAC @ 60 Hz

-

Motor

- Motor: Hagglunds CA70 hydraulic motor

-

Heat exchanger

- Heat exchanger: Water/oil standard

-

Fill system

- Fill system: Single jet fill, located at hydraulic tank

-

Filtration

- Filtration: Pressure and return line

- Overall length (mm): 10 923

- Overall length (in): 430

- Tram width (mm): 3 344

- Tram width (in): 132

- Minimum tran height (in): 38

- Minimum tran height (mm): 965

- Intake length (mm): 3 033

- Intake length (in): 119

- Maximum discharge clearance (mm): 762

- Maximum discharge clearance (in): 30

- Estimated Mass (lbs): 88,200

- Estimated Mass(kg): 40 000

- Conveyor width - single conveyor (mm): 1 422

- Conveyor width - single conveyor (in): 56

- Chain tensioning (in): 8 in stroke grease cylinders (one per side) with mechanical locking shims

- Chain tensioning (mm): 203 mm stroke grease cylinders (one per side) with mechanical locking shims

- Rationing: (2) Material Restricting chains – removeable

- Tail shift: 100 mm tailshaft with 100 mm take up bearings

- Government regulatory requirements: Not required

- State requirements: Not required

- Funk Planetary Gear Drive: Free-wheeling capabilities

- Crawlers (in): 15 in forged pad width with triple chevron grousers on engineered chain

- Crawlers (mm): 381 mm forged pad width with triple chevron grousers on engineered chain

- Chain tensioning: Grease cylinders with shim pack mechanical locks

- Tram speed (FPM): 47

- Tram speed (m/min): 14.3

- Intake end ground clearance (in): 2 - 22

- Intake end ground clearance (mm): 51 - 559

- Discharge end ground clearance (in): 2 - 22

- Discharge end ground clearance (mm): 51 - 559

- Telescopic cylinders: Include pilot operated check valves

- Mechanical elevation: Lock to isolate hydraulics

- Lubrication features: Manual central lube

- Breaker pick force (lbs): Up to 90,000

- Breaker pick force (kg): Up to 40 823

- Color: Orange per standard 5100036338 (Screens painted flat black)

- Throughput coal (60 lbf.-ft3): 1,200 TPH

- Throughput coal (962 kg/m3): 1 100 MTPH

- Throughput potash (75 lbf.-ft3): 1,700 TPH

- Throughput potash (1 201 kg/m3): 1 550 MTPH

- Throughput trona (75 lbf.-ft3): 1,700 TPH

- Throughput trona (1 201 kg/m3): 1 550 MTPH

- Throughput gypsum (80 lbf.-ft3): 1,500 TPH

- Throughput gypsum (1 281 kg/m3): 1 350 MTPH

- Max input size (in): 16

- Max input size (mm): 400

- Output size (in): 8

- Output size (mm): 204

- Conveyor width specifics (in): 56 single conveyor

- Conveyor width specifics (mm): 1 422 single conveyor

- Conveyor drive: Single shaft-mounted splined hydraulic motor and Hägglunds CA-70 or equivalent.

- Head shaft (in): 4.5-in head shaft with 3 15/16 in pillow block bearings and 9-tooth head shaft sprockets.

- Head shaft (mm): 114 mm head shaft with 100 mm pillow block bearings and 9-tooth head shaft sprockets.

- Tail shaft (in): 3.94 in tailshaft with 3.94 in take up bearings.

- Chain & flights (in): 3.5 in pitch, 220,000 lbf. ultimate strength per strand (440,000 lbf. total) with flight attachment pins every other pitch

- Chain & flights (mm): 89 mm pitch, 979 kN ultimate strength per strand (1 957 kN total) with flight attachment pins every other pitch

- Alloy steel flights, forged flight ends (in): 1.75 x 5

- Alloy steel flights, forged flight ends (mm): 44 x 126

- Flight spacing every 6th pitch (in): 21

- Flight spacing every 6th pitch (mm): 533

- (2) Material Restricting chains: Removeable

- Flat 3-way dump intake (in): 123 in long

- Flat 3-way dump intake (mm): 3 124 mm long

- Frame height (in): 36

- Frame height (mm): 914

- Conveyor wear deck: AR Plus

- CCO side chain: Wear strips on top and return decks

- Conveyor chain covers: Included

- Top covers: Steel

- Hinged rubber: Discharge chute

- Hopper sideboards: 6 in folding

- Breaker drive: Direct drive w/ splined connection to breaker shaft

- Relief: Torque limiting clutch

- Shaft: 200 mm diameter

-

Breaker

- Breaker (mm): 610 mm breaker diameter

- Breaker (in): 24 in breaker diameter

- Bearings specifics: 5 11/16 in

- Breaker picks: 1-piece tapered shank and heat treated with carbide inserts

- Weld-on holders: To be hard-surfaced

- Hard surfacing: Yes

- 5 nozzle spray bar (gpm) (psi): 5.2 gpm @ 150 psi per nozzle

- 5 nozzle spray bar (L/min) (bar): 19.7 L/min @ 10.3 bar per nozzle

- Pendulum valve: Activated when material is present in the conveyor

- Water inlet location: Conveyor drive side